The A9 Light Vehicle Diesel Engines covers diesel engine systems, including fuel injection, turbocharging, exhaust, and diagnostics. It’s an essential prep tool for the A9 certification exam.

Practice 9

Quiz-summary

0 of 56 questions completed

Questions:

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

Information

A9: Light Vehicle Diesel Engines

You have already completed the quiz before. Hence you can not start it again.

Quiz is loading...

You must sign in or sign up to start the quiz.

You have to finish following quiz, to start this quiz:

Results

0 of 56 questions answered correctly

Your time:

Time has elapsed

You have reached 0 of 0 points, (0)

| Average score |

|

| Your score |

|

Categories

- Not categorized 0%

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- Answered

- Review

-

Question 1 of 56

1. Question

1 pointsWhen measuring a cylinder for taper wear,

_________is the MOST suitable place for wear.Correct

The top of the cylinder is the most common area for wear because it experiences the highest temperatures during combustion. The repeated heating and cooling cause the metal to expand and contract, leading to gradual wear.

Cylinder taper wear refers to the difference in diameter between the top and bottom of the cylinder bore. It results from friction between the piston, rings, and combustion gases. Excessive taper can cause the piston rings to leak, leading to engine misfires, reduced power, and poor fuel economy.

To measure taper wear, a dial bore gauge is used. Measurements are taken at the top, middle, and bottom of the bore. The difference between the top and bottom readings indicates the amount of taper.

The acceptable taper limit varies by engine, so always refer to the manufacturer’s specifications for proper tolerances.

Incorrect

The top of the cylinder is the most common area for wear because it experiences the highest temperatures during combustion. The repeated heating and cooling cause the metal to expand and contract, leading to gradual wear.

Cylinder taper wear refers to the difference in diameter between the top and bottom of the cylinder bore. It results from friction between the piston, rings, and combustion gases. Excessive taper can cause the piston rings to leak, leading to engine misfires, reduced power, and poor fuel economy.

To measure taper wear, a dial bore gauge is used. Measurements are taken at the top, middle, and bottom of the bore. The difference between the top and bottom readings indicates the amount of taper.

The acceptable taper limit varies by engine, so always refer to the manufacturer’s specifications for proper tolerances.

-

Question 2 of 56

2. Question

1 pointsAll of the following assertions regarding precombustion chambers in a cylinder head are correct EXCEPT

_________.Correct

Precombustion chambers in the cylinder head may not require replacement if they have only minor cracks. Whether repair or replacement is needed depends on the severity of the damage and the engine’s design. In some cases, minor cracks can be repaired, while more serious damage may require replacement to ensure proper engine performance and reliability.

Incorrect

Precombustion chambers in the cylinder head may not require replacement if they have only minor cracks. Whether repair or replacement is needed depends on the severity of the damage and the engine’s design. In some cases, minor cracks can be repaired, while more serious damage may require replacement to ensure proper engine performance and reliability.

-

Question 3 of 56

3. Question

1 pointsAfter conducting a road test on the vehicle, the technician confirms a legitimate drive-ability concern raised by the customer. Upon connecting the scan tool to the diagnostic link connector, the technician should examine which of the following information to assess the potential efficacy of reprogramming the PCM/ECM?

Correct

When diagnosing a driveability concern, it’s important for the technician to check the calibration number of the Powertrain Control Module (PCM) or Engine Control Module (ECM) using a scan tool connected to the diagnostic link connector (DLC). This number identifies the current software version of the module.

If a newer calibration is available, reprogramming the PCM/ECM may help resolve performance issues or improve vehicle function. Manufacturers often release software updates to fix known problems, enhance efficiency, or optimize engine performance. Therefore, comparing the current calibration to the latest version is a key step in addressing driveability issues through reprogramming.

Incorrect

When diagnosing a driveability concern, it’s important for the technician to check the calibration number of the Powertrain Control Module (PCM) or Engine Control Module (ECM) using a scan tool connected to the diagnostic link connector (DLC). This number identifies the current software version of the module.

If a newer calibration is available, reprogramming the PCM/ECM may help resolve performance issues or improve vehicle function. Manufacturers often release software updates to fix known problems, enhance efficiency, or optimize engine performance. Therefore, comparing the current calibration to the latest version is a key step in addressing driveability issues through reprogramming.

-

Question 4 of 56

4. Question

1 pointsTechnician A thinks that a weak solution of antifreeze can result in corrosion build-up in the cooling system. Technician B thinks engine coolants and rust inhibitors could endure the lifetime of the diesel engine. Who is CORRECT?

Correct

Technician A is correct. A weak antifreeze solution can lead to corrosion buildup in the cooling system. Antifreeze contains corrosion inhibitors that protect metal components from rust and deterioration. If the concentration is too low, there may not be enough inhibitors to provide adequate protection, allowing corrosion to develop over time.

Technician B is incorrect. Most OEMs recommend changing the coolant at specific intervals because the corrosion inhibitors degrade over time. Once depleted, the coolant can no longer effectively protect the engine and cooling system components, increasing the risk of corrosion and potential damage. Regular coolant changes help replenish these inhibitors, ensuring continued protection and reliable system performance.

Incorrect

Technician A is correct. A weak antifreeze solution can lead to corrosion buildup in the cooling system. Antifreeze contains corrosion inhibitors that protect metal components from rust and deterioration. If the concentration is too low, there may not be enough inhibitors to provide adequate protection, allowing corrosion to develop over time.

Technician B is incorrect. Most OEMs recommend changing the coolant at specific intervals because the corrosion inhibitors degrade over time. Once depleted, the coolant can no longer effectively protect the engine and cooling system components, increasing the risk of corrosion and potential damage. Regular coolant changes help replenish these inhibitors, ensuring continued protection and reliable system performance.

-

Question 5 of 56

5. Question

1 pointsDuring the rebuilding process of a diesel engine equipped with piston oil cooling nozzles, Tech A suggests that the nozzles should be taken out and examined while disassembling. On the other hand, Tech B asserts that these nozzles need to be properly aligned when being reinstalled. Which technician is CORRECT?

Correct

Tech A is correct—removing and inspecting the nozzles during diesel engine disassembly is standard practice. This ensures they are clean, free of debris, and functioning properly. Inspection allows for any necessary cleaning, repair, or replacement before reassembly.

Tech B is also correct—proper alignment of the oil cooling nozzles during installation is critical. Misaligned nozzles may fail to direct oil onto the pistons correctly, resulting in poor cooling and potential engine damage. Accurate alignment is essential for reliable engine performance and longevity.

Incorrect

Tech A is correct—removing and inspecting the nozzles during diesel engine disassembly is standard practice. This ensures they are clean, free of debris, and functioning properly. Inspection allows for any necessary cleaning, repair, or replacement before reassembly.

Tech B is also correct—proper alignment of the oil cooling nozzles during installation is critical. Misaligned nozzles may fail to direct oil onto the pistons correctly, resulting in poor cooling and potential engine damage. Accurate alignment is essential for reliable engine performance and longevity.

-

Question 6 of 56

6. Question

1 pointsA diesel engine with an electronically managed solenoid pump and nozzles has an active diagnostic trouble code for a single cylinder #3 misfire with a rough idle at operating temperature. The cause should be

_________.Correct

If a replacement fuel line is shorter or longer than the original, it can affect the timing of fuel delivery, particularly to cylinder #3, potentially causing uneven idle or misfiring. Variations in fuel line length or routing can impact fuel pressure and delivery timing, which in turn affects combustion and engine performance.

A rough idle or misfire in a hot engine is not typically caused by a faulty glow plug, as glow plugs are primarily used during cold starts to preheat the combustion chamber. Once the engine is warm, they play little role in ongoing operation.

High Cetane fuel improves ignition quality with a shorter ignition delay, promoting smoother and more efficient combustion. It does not cause misfires.

In contrast, low Cetane fuel has poor ignition quality, leading to a longer delay before combustion. This can cause hard starting, white smoke, and misfiring, especially in cold conditions.

Incorrect

If a replacement fuel line is shorter or longer than the original, it can affect the timing of fuel delivery, particularly to cylinder #3, potentially causing uneven idle or misfiring. Variations in fuel line length or routing can impact fuel pressure and delivery timing, which in turn affects combustion and engine performance.

A rough idle or misfire in a hot engine is not typically caused by a faulty glow plug, as glow plugs are primarily used during cold starts to preheat the combustion chamber. Once the engine is warm, they play little role in ongoing operation.

High Cetane fuel improves ignition quality with a shorter ignition delay, promoting smoother and more efficient combustion. It does not cause misfires.

In contrast, low Cetane fuel has poor ignition quality, leading to a longer delay before combustion. This can cause hard starting, white smoke, and misfiring, especially in cold conditions.

-

Question 7 of 56

7. Question

1 pointsWhat factors can lead to the occurrence of brake fade?

Correct

Overheating of brake fluid is one of the key factors that can cause brake fade—a reduction in braking efficiency due to overheated brake components. When brake fluid becomes too hot, it loses its ability to effectively transfer hydraulic pressure, leading to diminished braking performance.

Other contributors to brake fade include excessive friction, worn brake pads or rotors, and insufficient cooling of the braking system.

Incorrect

Overheating of brake fluid is one of the key factors that can cause brake fade—a reduction in braking efficiency due to overheated brake components. When brake fluid becomes too hot, it loses its ability to effectively transfer hydraulic pressure, leading to diminished braking performance.

Other contributors to brake fade include excessive friction, worn brake pads or rotors, and insufficient cooling of the braking system.

-

Question 8 of 56

8. Question

1 pointsWhich part transforms kinetic energy into heat to decelerate the vehicle?

Correct

The brake rotor is a key component of the braking system that converts kinetic energy into heat to slow the vehicle. When the brake pads press against the spinning rotor, friction is generated, transforming the vehicle’s motion into heat energy. This process is essential for effective braking.

Incorrect

The brake rotor is a key component of the braking system that converts kinetic energy into heat to slow the vehicle. When the brake pads press against the spinning rotor, friction is generated, transforming the vehicle’s motion into heat energy. This process is essential for effective braking.

-

Question 9 of 56

9. Question

1 pointsWhich kind of brake is commonly employed for emergency or parking scenarios?

Correct

The hand brake, also called a parking brake or emergency brake, is primarily used to keep the vehicle stationary when parked or in emergency situations. It operates independently of the main hydraulic braking system and is manually engaged, typically with a lever or pedal. The hand brake usually applies braking force to the rear wheels.

Incorrect

The hand brake, also called a parking brake or emergency brake, is primarily used to keep the vehicle stationary when parked or in emergency situations. It operates independently of the main hydraulic braking system and is manually engaged, typically with a lever or pedal. The hand brake usually applies braking force to the rear wheels.

-

Question 10 of 56

10. Question

1 pointsIn which part of a vehicle should the primary fuel system supply side vacuum test take place?

Correct

The intake pipe of the high-pressure pump experiences the lowest pressure in the system, while positive pressure is present at the pump’s outlet. Similarly, positive pressure is also found at the inlet of the secondary air filter and on the inlet side of the primary filter.

Incorrect

The intake pipe of the high-pressure pump experiences the lowest pressure in the system, while positive pressure is present at the pump’s outlet. Similarly, positive pressure is also found at the inlet of the secondary air filter and on the inlet side of the primary filter.

-

Question 11 of 56

11. Question

1 pointsTechnician A claims that, during wide open throttle (WOT), the vanes in a variable geometry turbo (VGT) system are shut. In contrast, Technician B asserts that one can identify sticking vanes in a VGT system by examining the voltage readings of the Mass Air Flow (MAF) sensor on a scan tool. Who is CORRECT?

Correct

Technician A is incorrect. In a variable geometry turbo (VGT) system, the vanes are typically open at wide open throttle (WOT) to allow maximum exhaust flow and generate higher boost.

Technician B is also incorrect. While sticking vanes in a VGT system can impact engine performance, they are more reliably diagnosed by monitoring parameters like boost pressure or exhaust gas temperature. Although VGT issues may indirectly affect MAF sensor readings, the MAF is not a primary tool for diagnosing vane sticking.

Incorrect

Technician A is incorrect. In a variable geometry turbo (VGT) system, the vanes are typically open at wide open throttle (WOT) to allow maximum exhaust flow and generate higher boost.

Technician B is also incorrect. While sticking vanes in a VGT system can impact engine performance, they are more reliably diagnosed by monitoring parameters like boost pressure or exhaust gas temperature. Although VGT issues may indirectly affect MAF sensor readings, the MAF is not a primary tool for diagnosing vane sticking.

-

Question 12 of 56

12. Question

1 pointsWhile the engine is running, an infrared thermometer is used to scan a radiator, revealing that it is warmer near the inlet and cooler towards the outlet. Additionally, there are areas considerably cooler than the inlet. This temperature variation may be attributed to

_________.Correct

Cool areas on the radiator, despite the engine running and generating heat, may indicate mineral buildup. Over time, deposits can form on the radiator’s surfaces, acting as an insulator and reducing its ability to transfer heat. This results in uneven cooling and cooler spots on the radiator. Regular cleaning and maintenance are essential to prevent buildup and maintain efficient cooling system performance.

Incorrect

Cool areas on the radiator, despite the engine running and generating heat, may indicate mineral buildup. Over time, deposits can form on the radiator’s surfaces, acting as an insulator and reducing its ability to transfer heat. This results in uneven cooling and cooler spots on the radiator. Regular cleaning and maintenance are essential to prevent buildup and maintain efficient cooling system performance.

-

Question 13 of 56

13. Question

1 pointsThe MOST likely cause of a diesel engine vehicle consuming excessive oil, emitting blue smoke from the exhaust, experiencing abnormal noise from the turbocharger, and exhibiting oil stains around the turbocharger housing is

_________.Correct

Worn turbocharger seals can cause oil to leak into the exhaust system, leading to excessive oil consumption, blue smoke, and oil stains. Additionally, unusual turbocharger noise may result from the compromised seals affecting its operation. Prompt repair is essential to prevent further damage to both the engine and the turbocharger.

Incorrect

Worn turbocharger seals can cause oil to leak into the exhaust system, leading to excessive oil consumption, blue smoke, and oil stains. Additionally, unusual turbocharger noise may result from the compromised seals affecting its operation. Prompt repair is essential to prevent further damage to both the engine and the turbocharger.

-

Question 14 of 56

14. Question

1 pointsWhat is the commonly used brake fluid in the majority of modern vehicles?

Correct

ChatGPT said:

The most commonly used brake fluids in modern vehicles are DOT 3, DOT 4, and DOT 5.1, each defined by U.S. Department of Transportation (DOT) specifications. These types differ in their chemical composition and boiling points.

DOT 4 is widely used in many modern vehicles due to its higher boiling point compared to DOT 3, making it more effective under high-temperature conditions. To maintain proper brake system performance and safety, it’s essential to use the brake fluid type recommended by the vehicle manufacturer.

Incorrect

ChatGPT said:

The most commonly used brake fluids in modern vehicles are DOT 3, DOT 4, and DOT 5.1, each defined by U.S. Department of Transportation (DOT) specifications. These types differ in their chemical composition and boiling points.

DOT 4 is widely used in many modern vehicles due to its higher boiling point compared to DOT 3, making it more effective under high-temperature conditions. To maintain proper brake system performance and safety, it’s essential to use the brake fluid type recommended by the vehicle manufacturer.

-

Question 15 of 56

15. Question

1 pointsWhen disassembling a diesel engine equipped with wet cylinder sleeves, what actions should the technician take regarding the sleeves?

Correct

When disassembling a diesel engine with wet cylinder sleeves, the technician should carefully inspect the counterbore area for erosion, cracks, or other damage. This step is crucial to ensure proper sealing and the long-term reliability of the engine.

The counterbore is the recessed area in the engine block where the sleeve sits. Over time, it can become worn or eroded, which may lead to coolant leaks or poor sealing between the sleeve and the block. Cracks or other damage in this area can also affect engine performance.

Thorough inspection allows the technician to determine whether the sleeves need replacement or if the block requires repair. Addressing any issues at this stage helps ensure the engine will operate reliably after reassembly.

Incorrect

When disassembling a diesel engine with wet cylinder sleeves, the technician should carefully inspect the counterbore area for erosion, cracks, or other damage. This step is crucial to ensure proper sealing and the long-term reliability of the engine.

The counterbore is the recessed area in the engine block where the sleeve sits. Over time, it can become worn or eroded, which may lead to coolant leaks or poor sealing between the sleeve and the block. Cracks or other damage in this area can also affect engine performance.

Thorough inspection allows the technician to determine whether the sleeves need replacement or if the block requires repair. Addressing any issues at this stage helps ensure the engine will operate reliably after reassembly.

-

Question 16 of 56

16. Question

1 pointsWhich part is tasked with avoiding wheel lock-up when applying intense braking pressure?

Correct

The component responsible for preventing wheel lock-up during hard braking is the Anti-lock Brake System (ABS). This safety feature is standard in most modern vehicles and is designed to maintain steering control and stability during emergency or intense braking.

When the brakes are applied forcefully, the ABS monitors the rotational speed of each wheel. If it detects that a wheel is about to lock up, the system rapidly modulates brake pressure—automatically releasing and reapplying it several times per second. This allows the wheel to keep rotating and maintain traction with the road.

By preventing wheel lock-up, the ABS helps the driver maintain control, especially on slippery roads or during sudden stops, reducing the risk of skidding and improving overall vehicle safety.

Incorrect

The component responsible for preventing wheel lock-up during hard braking is the Anti-lock Brake System (ABS). This safety feature is standard in most modern vehicles and is designed to maintain steering control and stability during emergency or intense braking.

When the brakes are applied forcefully, the ABS monitors the rotational speed of each wheel. If it detects that a wheel is about to lock up, the system rapidly modulates brake pressure—automatically releasing and reapplying it several times per second. This allows the wheel to keep rotating and maintain traction with the road.

By preventing wheel lock-up, the ABS helps the driver maintain control, especially on slippery roads or during sudden stops, reducing the risk of skidding and improving overall vehicle safety.

-

Question 17 of 56

17. Question

1 pointsA diesel engine vehicle has encountered recurring glow plug failures. Tech A suggests that a faulty glow plug relay could be the cause, while Tech B proposes that a defective control module might be responsible. Which technician is CORRECT?

Correct

The glow plug relay controls power delivery to the glow plugs in a diesel engine. If the relay is defective, it may fail to supply adequate power, leading to repeated glow plug failures. In this case, the relay could be the root cause of the issue.

Similarly, the engine control module (ECM) manages various engine functions, including the operation of the glow plugs. If the ECM is malfunctioning, it may fail to send the correct signals to the glow plug relay, which can also result in glow plug failure.

In summary, both Technician A and Technician B could be correct. A faulty glow plug relay or a malfunctioning control module can each cause repeated glow plug failure. A complete diagnostic test is essential to determine the exact source of the problem.

Incorrect

The glow plug relay controls power delivery to the glow plugs in a diesel engine. If the relay is defective, it may fail to supply adequate power, leading to repeated glow plug failures. In this case, the relay could be the root cause of the issue.

Similarly, the engine control module (ECM) manages various engine functions, including the operation of the glow plugs. If the ECM is malfunctioning, it may fail to send the correct signals to the glow plug relay, which can also result in glow plug failure.

In summary, both Technician A and Technician B could be correct. A faulty glow plug relay or a malfunctioning control module can each cause repeated glow plug failure. A complete diagnostic test is essential to determine the exact source of the problem.

-

Question 18 of 56

18. Question

1 pointsA vehicle is experiencing reduced power when under load. What might be causing this?

Correct

A leaking charge air cooler (intercooler) can be a potential cause of low engine power under load. The charge air cooler cools compressed air before it enters the engine, increasing air density for better combustion. If it leaks, boost pressure drops, reducing the amount of air available for combustion. This results in poor engine performance, especially under load, leading to reduced power, inefficient combustion, and overall decreased engine efficiency.

Incorrect

A leaking charge air cooler (intercooler) can be a potential cause of low engine power under load. The charge air cooler cools compressed air before it enters the engine, increasing air density for better combustion. If it leaks, boost pressure drops, reducing the amount of air available for combustion. This results in poor engine performance, especially under load, leading to reduced power, inefficient combustion, and overall decreased engine efficiency.

-

Question 19 of 56

19. Question

1 pointsThe outcomes of a compression test on two neighboring cylinders reveal low pressure in both. Technician A suggests that a cracked head gasket could be the cause, while Technician B proposes that a cracked block might be the issue. Who is CORRECT?

Correct

A cracked head gasket can lead to compression loss between cylinders, resulting in low pressure readings in both. The head gasket sits between the cylinder head and engine block, sealing the combustion chambers and preventing the mixing of coolant, oil, and combustion gases. If it fails, compression may leak from one cylinder to another, reducing pressure in multiple cylinders.

Similarly, a cracked engine block can also cause compression loss. The engine block houses the cylinders and other key components, and any crack in this structure can compromise the seal between cylinders, leading to low compression in adjacent cylinders.

Incorrect

A cracked head gasket can lead to compression loss between cylinders, resulting in low pressure readings in both. The head gasket sits between the cylinder head and engine block, sealing the combustion chambers and preventing the mixing of coolant, oil, and combustion gases. If it fails, compression may leak from one cylinder to another, reducing pressure in multiple cylinders.

Similarly, a cracked engine block can also cause compression loss. The engine block houses the cylinders and other key components, and any crack in this structure can compromise the seal between cylinders, leading to low compression in adjacent cylinders.

-

Question 20 of 56

20. Question

1 pointsA mechanic partially removes coolant from a diesel vehicle’s engine to replace an upper radiator hose. After the repair, the mechanic refills the cooling system with a 50/50 blend of IAT (Inorganic Technology) antifreeze and water. Nevertheless, the owner’s manual specifies the need for HOAT (Hybrid Organic Additive Technology) antifreeze. Tech A suggests that this mismatch could lead to potential overheating and insufficient freeze protection, while Tech B contends that the coolant should be replaced sooner. Which technician is CORRECT?

Correct

ChatGPT said:

Tech B is correct. Mixing different types of antifreeze can negatively affect the vehicle’s cooling system. In this case, the technician added a 50/50 mix of IAT antifreeze, while the owner’s manual specifies HOAT antifreeze.

IAT and HOAT coolants have different chemical formulations and additive packages. Mixing them can cause chemical reactions that reduce coolant effectiveness and may damage components in the cooling system.

Using the wrong type of antifreeze can result in insufficient freeze protection, poor corrosion resistance, and reduced cooling performance. Over time, this may lead to overheating or cooling system failure.

Incorrect

ChatGPT said:

Tech B is correct. Mixing different types of antifreeze can negatively affect the vehicle’s cooling system. In this case, the technician added a 50/50 mix of IAT antifreeze, while the owner’s manual specifies HOAT antifreeze.

IAT and HOAT coolants have different chemical formulations and additive packages. Mixing them can cause chemical reactions that reduce coolant effectiveness and may damage components in the cooling system.

Using the wrong type of antifreeze can result in insufficient freeze protection, poor corrosion resistance, and reduced cooling performance. Over time, this may lead to overheating or cooling system failure.

-

Question 21 of 56

21. Question

1 pointsIf the oil pressure warning light persists while a diesel engine is in operation, what steps should the technician take next?

Correct

The oil pressure warning light is an indication that the oil pressure in the engine is below the recommended level.

Low oil pressure can be caused by various factors, such as insufficient oil in the engine or a malfunctioning oil pump. However, before considering more complex issues, it is important to first verify the oil level. A low oil level can lead to decreased oil pressure and potential damage to the engine if not addressed promptly.

The technician should check the engine oil level using the dipstick or any other appropriate method as specified in the engine’s manufacturer guidelines. If the oil level is found to be low, the technician should add the appropriate amount of oil to bring it to the recommended level.Incorrect

The oil pressure warning light is an indication that the oil pressure in the engine is below the recommended level.

Low oil pressure can be caused by various factors, such as insufficient oil in the engine or a malfunctioning oil pump. However, before considering more complex issues, it is important to first verify the oil level. A low oil level can lead to decreased oil pressure and potential damage to the engine if not addressed promptly.

The technician should check the engine oil level using the dipstick or any other appropriate method as specified in the engine’s manufacturer guidelines. If the oil level is found to be low, the technician should add the appropriate amount of oil to bring it to the recommended level. -

Question 22 of 56

22. Question

1 pointsWhat is the MOST appropriate chemical that should be sprayed on a diesel block and crankshaft after having been cleaned?

Correct

After cleaning a diesel engine block and crankshaft, it’s important to apply a rust inhibitor to prevent corrosion during storage. To further protect the components, you can also wrap them in plastic to shield them from moisture and other environmental elements.

Here are common rust inhibitor options for a diesel block and crankshaft:

-

Wax: Easy to apply and remove, wax offers decent protection in dry environments. However, it can wash away with water and may require reapplication in humid or wet conditions.

-

Oil: Provides stronger rust protection than wax, especially in wet environments. While effective, oil can be messy, harder to clean, and tends to attract dirt and debris.

-

Grease: Offers excellent rust protection and lubrication, helping extend the life of metal parts. However, it’s thick, messy, and more difficult to remove than oil or wax.

-

Paint: A durable and long-lasting option that also improves appearance. It provides good rust protection but can be expensive and time-consuming to apply.

-

Chromate conversion coating: Creates a highly protective chemical layer on metal surfaces. This is the most effective option but also the most expensive and typically used in industrial applications.

The best rust inhibitor depends on the storage environment, duration of storage, and ease of application. For most diesel engine components, a wax- or oil-based inhibitor strikes a good balance of affordability, ease of use, and reliable protection.

Incorrect

After cleaning a diesel engine block and crankshaft, it’s important to apply a rust inhibitor to prevent corrosion during storage. To further protect the components, you can also wrap them in plastic to shield them from moisture and other environmental elements.

Here are common rust inhibitor options for a diesel block and crankshaft:

-

Wax: Easy to apply and remove, wax offers decent protection in dry environments. However, it can wash away with water and may require reapplication in humid or wet conditions.

-

Oil: Provides stronger rust protection than wax, especially in wet environments. While effective, oil can be messy, harder to clean, and tends to attract dirt and debris.

-

Grease: Offers excellent rust protection and lubrication, helping extend the life of metal parts. However, it’s thick, messy, and more difficult to remove than oil or wax.

-

Paint: A durable and long-lasting option that also improves appearance. It provides good rust protection but can be expensive and time-consuming to apply.

-

Chromate conversion coating: Creates a highly protective chemical layer on metal surfaces. This is the most effective option but also the most expensive and typically used in industrial applications.

The best rust inhibitor depends on the storage environment, duration of storage, and ease of application. For most diesel engine components, a wax- or oil-based inhibitor strikes a good balance of affordability, ease of use, and reliable protection.

-

Question 23 of 56

23. Question

1 pointsA severe oil leak at the rocker cover is found on light duty diesel engine. Despite the rocker cover gasket replacement, the gasket still leaks. What is the MOST feasible reason?

Correct

ChatGPT said:

The most likely cause of a severe oil leak at the rocker cover is a stuck-closed CDR (Crankcase Depression Regulator) valve. When the CDR is not functioning properly, it causes excess crankcase pressure, which can force oil past the rocker cover gasket, resulting in a leak.

If the rocker cover gasket has already been replaced and the leak persists, the next step is to inspect the CDR valve. To check it, disconnect the hose and try blowing through the CDR. If air does not pass through easily, the valve is stuck closed and should be replaced to restore proper crankcase ventilation and prevent further leaks.

Incorrect

ChatGPT said:

The most likely cause of a severe oil leak at the rocker cover is a stuck-closed CDR (Crankcase Depression Regulator) valve. When the CDR is not functioning properly, it causes excess crankcase pressure, which can force oil past the rocker cover gasket, resulting in a leak.

If the rocker cover gasket has already been replaced and the leak persists, the next step is to inspect the CDR valve. To check it, disconnect the hose and try blowing through the CDR. If air does not pass through easily, the valve is stuck closed and should be replaced to restore proper crankcase ventilation and prevent further leaks.

-

Question 24 of 56

24. Question

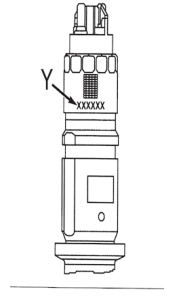

1 pointsThe replacement of an electronic fuel injector is underway in a diesel engine featuring a high-pressure common rail injection system. The details highlighted at point Y in the provided illustration signify the characteristics of the injector

_________. Correct

Correct

In a high-pressure common rail injection system, each electronic fuel injector is individually calibrated and coded with specific data. This calibration code contains key parameters such as fuel delivery rates, injection timing, and other values essential for accurate engine performance.

When replacing an injector, it’s crucial to ensure the new injector’s calibration code is properly entered into the engine control unit (ECU). This allows the ECU to precisely manage fuel delivery, ensuring the injector operates correctly and maintains optimal engine efficiency and performance.

Incorrect

In a high-pressure common rail injection system, each electronic fuel injector is individually calibrated and coded with specific data. This calibration code contains key parameters such as fuel delivery rates, injection timing, and other values essential for accurate engine performance.

When replacing an injector, it’s crucial to ensure the new injector’s calibration code is properly entered into the engine control unit (ECU). This allows the ECU to precisely manage fuel delivery, ensuring the injector operates correctly and maintains optimal engine efficiency and performance.

-

Question 25 of 56

25. Question

1 pointsAll of the following reasons could potentially be responsible for the presence of a milky gray sludge in the radiator and the milky appearance of the engine oil EXCEPT

_________.Correct

Defective water pump bearings can potentially cause milky gray sludge in the radiator and milky engine oil, as bearing failure may allow coolant to leak into the engine oil, creating the milky mixture. However, it’s important to note that this symptom can have multiple possible causes, such as a blown head gasket or a cracked engine block. Without further diagnostics, the exact cause cannot be confirmed.

Incorrect

Defective water pump bearings can potentially cause milky gray sludge in the radiator and milky engine oil, as bearing failure may allow coolant to leak into the engine oil, creating the milky mixture. However, it’s important to note that this symptom can have multiple possible causes, such as a blown head gasket or a cracked engine block. Without further diagnostics, the exact cause cannot be confirmed.

-

Question 26 of 56

26. Question

1 pointsA diesel vehicle equipped with a HEUI (Hydraulic Electronic Unit Injector) fuel system initiates and idles without issue, but fails to attain regular power levels. What might be the potential scenario?

Correct

If a diesel engine with a HEUI (Hydraulic Electronic Unit Injector) system starts and idles normally but lacks full power, one likely cause is insufficient turbo boost. The turbocharger is essential for delivering compressed air to the engine, supporting efficient combustion and maximizing power output.

Low boost pressure can result from several issues, including a faulty or damaged turbocharger, intake restrictions, intercooler leaks, or wastegate malfunctions. Without adequate boost, the engine cannot reach its optimal power levels, even if it runs smoothly at idle.

Incorrect

If a diesel engine with a HEUI (Hydraulic Electronic Unit Injector) system starts and idles normally but lacks full power, one likely cause is insufficient turbo boost. The turbocharger is essential for delivering compressed air to the engine, supporting efficient combustion and maximizing power output.

Low boost pressure can result from several issues, including a faulty or damaged turbocharger, intake restrictions, intercooler leaks, or wastegate malfunctions. Without adequate boost, the engine cannot reach its optimal power levels, even if it runs smoothly at idle.

-

Question 27 of 56

27. Question

1 pointsA diesel engine equipped with a high-pressure common rail (HPCR) system is undergoing diagnosis due to a crank/no-start issue. In the course of testing, a manual gauge is installed, revealing low fuel rail pressure. What could be the potential cause among the following options?

Correct

In a high-pressure common rail (HPCR) diesel engine, the fuel rail pressure control valve regulates the pressure within the fuel rail to ensure proper fuel delivery. If this valve fails or becomes stuck, it can lead to low fuel rail pressure, which may cause hard starting or prevent the engine from starting altogether.

Incorrect

In a high-pressure common rail (HPCR) diesel engine, the fuel rail pressure control valve regulates the pressure within the fuel rail to ensure proper fuel delivery. If this valve fails or becomes stuck, it can lead to low fuel rail pressure, which may cause hard starting or prevent the engine from starting altogether.

-

Question 28 of 56

28. Question

1 pointsAn oil bypass valve will open under all conditions EXCEPT

_________.Correct

The oil bypass valve is designed to open when oil pressure is low, such as during cold starts or when the oil is thick and highly viscous. This allows oil to continue circulating through the engine even if the oil filter is partially or fully clogged, ensuring continued lubrication. When oil pressure is high, the bypass valve typically remains closed, as sufficient pressure is already available to maintain proper lubrication.

Incorrect

The oil bypass valve is designed to open when oil pressure is low, such as during cold starts or when the oil is thick and highly viscous. This allows oil to continue circulating through the engine even if the oil filter is partially or fully clogged, ensuring continued lubrication. When oil pressure is high, the bypass valve typically remains closed, as sufficient pressure is already available to maintain proper lubrication.

-

Question 29 of 56

29. Question

1 pointsAn examination is being conducted on a rubber-bound vibration damper, and it is recommended for replacement if any of the listed issues are present EXCEPT

_________.Correct

Rubber-bound vibration dampers, also known as isolators, are used to absorb and reduce vibrations in engines, machinery, and other equipment. They usually feature a metal core bonded to a rubber outer layer. While the presence of oil may warrant attention depending on its source and behavior, outward-radiating streaks on the damper are not typically a sign of a serious problem. However, further inspection may be needed to confirm the condition.

Incorrect

Rubber-bound vibration dampers, also known as isolators, are used to absorb and reduce vibrations in engines, machinery, and other equipment. They usually feature a metal core bonded to a rubber outer layer. While the presence of oil may warrant attention depending on its source and behavior, outward-radiating streaks on the damper are not typically a sign of a serious problem. However, further inspection may be needed to confirm the condition.

-

Question 30 of 56

30. Question

1 pointsWhen connecting

_________to the Data Link Connector, it allows the technician to read light duty diesel engine diagnostic trouble codes.Correct

When diagnosing trouble codes in a vehicle’s engine control system, a diagnostic scan tool or a laptop with the appropriate interface is typically used. These tools connect to the vehicle’s onboard computer via the Data Link Connector (DLC) to retrieve Diagnostic Trouble Codes (DTCs) and related data.

In contrast, a Digital Multimeter (DMM) is primarily used for electrical testing, such as measuring voltage, current, and resistance, or diagnosing wiring and circuit issues. It is not designed to retrieve DTCs from the engine control module

Incorrect

When diagnosing trouble codes in a vehicle’s engine control system, a diagnostic scan tool or a laptop with the appropriate interface is typically used. These tools connect to the vehicle’s onboard computer via the Data Link Connector (DLC) to retrieve Diagnostic Trouble Codes (DTCs) and related data.

In contrast, a Digital Multimeter (DMM) is primarily used for electrical testing, such as measuring voltage, current, and resistance, or diagnosing wiring and circuit issues. It is not designed to retrieve DTCs from the engine control module

-

Question 31 of 56

31. Question

1 pointsWhen assessing the starter current draw in a diesel engine vehicle, if the recorded value exceeds the specified limits, what might be the potential cause among the following options?

Correct

A decrease in resistance within the starter circuit means that electrical current faces less opposition as it flows. This can result from corroded or damaged connections, faulty components, or worn wiring.

According to Ohm’s Law (V = I × R), if voltage (V) remains constant and resistance (R) decreases, the current (I) will increase. In a starter motor circuit, lower resistance allows more current to flow, potentially leading to a higher-than-normal current draw, which may indicate an underlying issue.

Incorrect

A decrease in resistance within the starter circuit means that electrical current faces less opposition as it flows. This can result from corroded or damaged connections, faulty components, or worn wiring.

According to Ohm’s Law (V = I × R), if voltage (V) remains constant and resistance (R) decreases, the current (I) will increase. In a starter motor circuit, lower resistance allows more current to flow, potentially leading to a higher-than-normal current draw, which may indicate an underlying issue.

-

Question 32 of 56

32. Question

1 pointsExcept for

_________, each of the following factors has the potential to produce white smoke from a diesel engine’s exhaust.Correct

Leaking injectors typically cause a rich air/fuel mixture, resulting in black smoke from the exhaust. In contrast, the other conditions listed can produce white smoke in a diesel engine.

A lean air/fuel mixture, dirty injectors leading to poor fuel delivery, or faulty glow plugs that prevent efficient combustion during cold starts can all contribute to white smoke, often due to unburned fuel or incomplete combustion.

Incorrect

Leaking injectors typically cause a rich air/fuel mixture, resulting in black smoke from the exhaust. In contrast, the other conditions listed can produce white smoke in a diesel engine.

A lean air/fuel mixture, dirty injectors leading to poor fuel delivery, or faulty glow plugs that prevent efficient combustion during cold starts can all contribute to white smoke, often due to unburned fuel or incomplete combustion.

-

Question 33 of 56

33. Question

1 pointsIf the height of a wet cylinder sleeve is not within specifications during installation, what action should the technician take?

Correct

If the sleeve height is out of specification during the installation of a wet cylinder sleeve, the technician should install a shim under the sleeve flange. This shim helps adjust the sleeve height to ensure proper alignment with surrounding engine components.

Correct sleeve height is crucial for maintaining proper compression and sealing within the cylinder. Using a shim ensures precise fitment, which helps prevent leaks, uneven wear, and other performance issues, supporting optimal engine function.

Incorrect

If the sleeve height is out of specification during the installation of a wet cylinder sleeve, the technician should install a shim under the sleeve flange. This shim helps adjust the sleeve height to ensure proper alignment with surrounding engine components.

Correct sleeve height is crucial for maintaining proper compression and sealing within the cylinder. Using a shim ensures precise fitment, which helps prevent leaks, uneven wear, and other performance issues, supporting optimal engine function.

-

Question 34 of 56

34. Question

1 pointsWhich part is tasked with conveying the force from the brake pedal to the braking system?

Correct

The master cylinder is a key component in a vehicle’s braking system, responsible for converting brake pedal force into hydraulic pressure. When the brake pedal is pressed, the master cylinder generates pressure that travels through the brake lines to the calipers or wheel cylinders. This activates the brake pads or shoes, slowing or stopping the vehicle. As the heart of the hydraulic brake system, the master cylinder plays a crucial role in braking performance and safety.

Incorrect

The master cylinder is a key component in a vehicle’s braking system, responsible for converting brake pedal force into hydraulic pressure. When the brake pedal is pressed, the master cylinder generates pressure that travels through the brake lines to the calipers or wheel cylinders. This activates the brake pads or shoes, slowing or stopping the vehicle. As the heart of the hydraulic brake system, the master cylinder plays a crucial role in braking performance and safety.

-

Question 35 of 56

35. Question

1 pointsWhen inspecting the monitor status using a scan tool, if a technician comes across a monitor labeled as “incomplete,” it signifies that

_________.Correct

When a monitor is marked as “incomplete” on a scan tool, it means the vehicle has not yet met the specific drive cycle conditions required for that monitor to finish its self-test. Until those conditions are satisfied through normal driving, the monitor will remain incomplete.

This status is part of the On-Board Diagnostics (OBD) system, which uses monitors to continuously evaluate the performance of various components and systems to ensure they are operating correctly.

Incorrect

When a monitor is marked as “incomplete” on a scan tool, it means the vehicle has not yet met the specific drive cycle conditions required for that monitor to finish its self-test. Until those conditions are satisfied through normal driving, the monitor will remain incomplete.

This status is part of the On-Board Diagnostics (OBD) system, which uses monitors to continuously evaluate the performance of various components and systems to ensure they are operating correctly.

-

Question 36 of 56

36. Question

1 pointsA diesel engine exhibits oil leakage and, upon testing, is determined to have excessive crankcase pressure. Tech A suggests that worn rings could be the cause of the excessive crankcase pressure. Tech B, on the other hand, suggests that a restricted crankcase breather tube could be the cause. Which technician is CORRECT?

Correct

Excessive crankcase pressure in a diesel engine can be caused by both worn piston rings and a restricted crankcase breather tube:

-

Worn piston rings: These rings seal the gap between the piston and cylinder wall. When they wear out or get damaged, combustion gases leak past the rings (blow-by) and enter the crankcase, raising internal pressure.

-

Restricted crankcase breather tube: This tube vents pressure and gases from the crankcase. If it becomes blocked or restricted, it prevents proper ventilation, causing pressure to build up inside the crankcase.

Incorrect

Excessive crankcase pressure in a diesel engine can be caused by both worn piston rings and a restricted crankcase breather tube:

-

Worn piston rings: These rings seal the gap between the piston and cylinder wall. When they wear out or get damaged, combustion gases leak past the rings (blow-by) and enter the crankcase, raising internal pressure.

-

Restricted crankcase breather tube: This tube vents pressure and gases from the crankcase. If it becomes blocked or restricted, it prevents proper ventilation, causing pressure to build up inside the crankcase.

-

Question 37 of 56

37. Question

1 pointsAll of the following factors can lead to the emission of black smoke from a diesel engine’s exhaust EXCEPT _________.

Correct

Black smoke from a diesel engine’s exhaust usually indicates too much fuel is being burned. This results from an imbalanced air-to-fuel ratio, where excess fuel exceeds the available oxygen for complete combustion. Although several issues can cause black smoke, low fuel pressure is not one of them. In fact, low fuel pressure generally leads to a lean mixture, which may cause reduced power or engine hesitation—but not black smoke.

Incorrect

Black smoke from a diesel engine’s exhaust usually indicates too much fuel is being burned. This results from an imbalanced air-to-fuel ratio, where excess fuel exceeds the available oxygen for complete combustion. Although several issues can cause black smoke, low fuel pressure is not one of them. In fact, low fuel pressure generally leads to a lean mixture, which may cause reduced power or engine hesitation—but not black smoke.

-

Question 38 of 56

38. Question

1 pointsAfter the replacement of a

_________, valve adjustment is required.Correct

After replacing a cylinder head, valve adjustment is necessary. The cylinder head houses the intake and exhaust valves, which regulate airflow and exhaust in the engine. Valve adjustment ensures the correct clearance between the valve stem and the rocker arm or camshaft, allowing the valves to open and close properly without causing damage. Since replacing the cylinder head can alter these clearances, a valve adjustment is essential to restore proper engine function.

Incorrect

After replacing a cylinder head, valve adjustment is necessary. The cylinder head houses the intake and exhaust valves, which regulate airflow and exhaust in the engine. Valve adjustment ensures the correct clearance between the valve stem and the rocker arm or camshaft, allowing the valves to open and close properly without causing damage. Since replacing the cylinder head can alter these clearances, a valve adjustment is essential to restore proper engine function.

-

Question 39 of 56

39. Question

1 pointsOn a cold winter morning, a diesel engine might face difficulties starting. All of the following factors could be a potential cause leading to this issue, except for

_________.Correct

N/A

Incorrect

N/A

-

Question 40 of 56

40. Question

1 pointsWhat should be employed to locate a coolant-leaking injector sleeve among the given options?

Correct

Pressure testing involves using specialized equipment to pressurize the cooling system. By applying pressure, technicians can detect leaks—such as those from an injector sleeve—by watching for visible coolant leaks or a drop in system pressure. This method is a standard diagnostic tool for identifying cooling system problems and locating the exact source of a leak.

Incorrect

Pressure testing involves using specialized equipment to pressurize the cooling system. By applying pressure, technicians can detect leaks—such as those from an injector sleeve—by watching for visible coolant leaks or a drop in system pressure. This method is a standard diagnostic tool for identifying cooling system problems and locating the exact source of a leak.

-

Question 41 of 56

41. Question

1 pointsA diagnostic trouble code (DTC) is currently active in an electronic diesel engine, indicating a misfire in Cylinder #3. The potential cause of this issue includes

_________.Correct

Low compression in cylinder #3 may be the underlying cause of a diagnostic trouble code (DTC) indicating a “Cylinder #3 Misfire” in an electronic diesel engine. Inadequate compression can result in incomplete combustion, which leads to a misfire. This condition is detected by the engine control module (ECM), which then sets the corresponding trouble code.

Common causes of low compression include worn piston rings, damaged cylinder walls, leaking head gaskets, or faulty valves. To accurately identify the root of the problem, a comprehensive diagnostic approach—such as a compression test and a detailed inspection of related engine components—is required.

Incorrect

Low compression in cylinder #3 may be the underlying cause of a diagnostic trouble code (DTC) indicating a “Cylinder #3 Misfire” in an electronic diesel engine. Inadequate compression can result in incomplete combustion, which leads to a misfire. This condition is detected by the engine control module (ECM), which then sets the corresponding trouble code.

Common causes of low compression include worn piston rings, damaged cylinder walls, leaking head gaskets, or faulty valves. To accurately identify the root of the problem, a comprehensive diagnostic approach—such as a compression test and a detailed inspection of related engine components—is required.

-

Question 42 of 56

42. Question

1 pointsA diesel engine experiences pronounced vibrations when idling. Among the following options, all could be potential causes EXCEPT

_________.Correct

A stuck-closed EGR (Exhaust Gas Recirculation) valve is unlikely to cause severe vibration at idle in a diesel engine. The EGR valve’s role is to redirect a portion of exhaust gases back into the intake to reduce emissions. If the valve is stuck closed, it usually leads to symptoms like increased NOx emissions, reduced fuel efficiency, or rough operation at higher engine speeds—not significant vibration at idle.

Incorrect

A stuck-closed EGR (Exhaust Gas Recirculation) valve is unlikely to cause severe vibration at idle in a diesel engine. The EGR valve’s role is to redirect a portion of exhaust gases back into the intake to reduce emissions. If the valve is stuck closed, it usually leads to symptoms like increased NOx emissions, reduced fuel efficiency, or rough operation at higher engine speeds—not significant vibration at idle.

-

Question 43 of 56

43. Question

1 pointsEXCEPT_______, all of the following factors can result in insufficient boost from a turbocharger.

Correct

An exhaust leak downstream of the turbine is unlikely to cause insufficient turbocharger boost. In fact, such a leak generally allows exhaust gases to flow more freely, which can lead to increased turbine speed and potentially result in higher boost levels or even over-boost conditions.

Incorrect

An exhaust leak downstream of the turbine is unlikely to cause insufficient turbocharger boost. In fact, such a leak generally allows exhaust gases to flow more freely, which can lead to increased turbine speed and potentially result in higher boost levels or even over-boost conditions.

-

Question 44 of 56

44. Question

1 pointsWhat is the objective of machining brake rotors?

Correct

The purpose of machining brake rotors is to restore their parallelism and surface finish. Over time, rotors can develop uneven wear and surface imperfections that impact braking performance. Machining—also called turning or resurfacing—involves removing a thin layer of material from the rotor surface to create a smooth, even finish. This process ensures both rotor faces are parallel and enhances the contact between the brake pads and rotor, resulting in more effective and consistent braking.

Incorrect

The purpose of machining brake rotors is to restore their parallelism and surface finish. Over time, rotors can develop uneven wear and surface imperfections that impact braking performance. Machining—also called turning or resurfacing—involves removing a thin layer of material from the rotor surface to create a smooth, even finish. This process ensures both rotor faces are parallel and enhances the contact between the brake pads and rotor, resulting in more effective and consistent braking.

-

Question 45 of 56

45. Question

1 pointsTech A asserts that a dual mass flywheel should be replaced when the clutch surface shows signs of cracking, scoring, or excessive wear. On the other hand, Tech B claims that a dual mass flywheel should be replaced if the teeth on the ring gear exhibit wear or damage. Which technician is CORRECT?

Correct

Tech A is correct. A dual mass flywheel should be replaced if the clutch surface is cracked, scored, or excessively worn. This surface is where the clutch disc engages and disengages, and any damage can lead to clutch slippage, poor engagement, or other drivability issues. In such cases, replacement of the flywheel is typically required.

Tech B is incorrect. While the ring gear—part of the flywheel that engages with the starter motor—can become worn or damaged, its condition alone doesn’t justify replacing the entire dual mass flywheel. If only the ring gear is affected, it may be possible to replace or repair just that component without replacing the entire flywheel.

Incorrect

Tech A is correct. A dual mass flywheel should be replaced if the clutch surface is cracked, scored, or excessively worn. This surface is where the clutch disc engages and disengages, and any damage can lead to clutch slippage, poor engagement, or other drivability issues. In such cases, replacement of the flywheel is typically required.

Tech B is incorrect. While the ring gear—part of the flywheel that engages with the starter motor—can become worn or damaged, its condition alone doesn’t justify replacing the entire dual mass flywheel. If only the ring gear is affected, it may be possible to replace or repair just that component without replacing the entire flywheel.

-

Question 46 of 56

46. Question

1 pointsA Catalyzed Diesel Particulate Filter requires what kind of oil?

Correct

A Catalyzed Diesel Particulate Filter (CDPF) requires oil with a low ash content. The CDPF is a device that is designed to remove particulate matter (soot) from the exhaust gases of a diesel engine. It contains a catalyst that promotes the oxidation of the soot particles, which are then trapped in the filter. To ensure the proper operation of the CDPF, it is important to use oil with a low ash content, as high ash content oils can produce ash deposits that can clog the filter and reduce its effectiveness. Therefore, it is important to use oil that meets the manufacturer’s specifications for the particular engine and CDPF system being used. In addition, the use of low-sulfur diesel fuel is also recommended to reduce the formation of soot and other pollutants in the exhaust gases.

Incorrect

A Catalyzed Diesel Particulate Filter (CDPF) requires oil with a low ash content. The CDPF is a device that is designed to remove particulate matter (soot) from the exhaust gases of a diesel engine. It contains a catalyst that promotes the oxidation of the soot particles, which are then trapped in the filter. To ensure the proper operation of the CDPF, it is important to use oil with a low ash content, as high ash content oils can produce ash deposits that can clog the filter and reduce its effectiveness. Therefore, it is important to use oil that meets the manufacturer’s specifications for the particular engine and CDPF system being used. In addition, the use of low-sulfur diesel fuel is also recommended to reduce the formation of soot and other pollutants in the exhaust gases.

-

Question 47 of 56

47. Question

1 pointsUpon disassembling an oil pump, it is discovered that the oil pressure relief valve piston is scored and exhibits difficulty moving within its bore. Regarding the potential reuse of this piston, Tech A suggests that it would result in excessive oil pressure, while Tech B contends that it would lead to low or no oil pressure. Which technician is CORRECT?

Correct

A Catalyzed Diesel Particulate Filter (CDPF) requires engine oil with low ash content to function properly. The CDPF is designed to capture and oxidize soot particles from a diesel engine’s exhaust. Using high-ash oil can lead to ash buildup in the filter, which may cause clogging and reduce its efficiency. To prevent this, it’s essential to use oil that meets the manufacturer’s specifications for both the engine and CDPF system. Additionally, using low-sulfur diesel fuel helps minimize soot formation and further supports cleaner, more efficient operation of the emissions system.

Incorrect

A Catalyzed Diesel Particulate Filter (CDPF) requires engine oil with low ash content to function properly. The CDPF is designed to capture and oxidize soot particles from a diesel engine’s exhaust. Using high-ash oil can lead to ash buildup in the filter, which may cause clogging and reduce its efficiency. To prevent this, it’s essential to use oil that meets the manufacturer’s specifications for both the engine and CDPF system. Additionally, using low-sulfur diesel fuel helps minimize soot formation and further supports cleaner, more efficient operation of the emissions system.

-

Question 48 of 56

48. Question

1 pointsA diesel engine exhibits a pronounced knocking sound that disappears when the clutch pedal is pressed. Technician A suggests that worn main bearings might be the culprit, while Technician B proposes that excessive crankshaft end-play could be the cause. Who is CORRECT

Correct

Excessive crankshaft end-play—movement along the crankshaft’s axis—can produce a knocking noise in a diesel engine. When the clutch pedal is pressed, the load on the crankshaft changes, which can temporarily reduce or eliminate the noise. While worn main bearings can also cause knocking, the fact that the noise disappears when the clutch is engaged more strongly suggests that excessive crankshaft end-play is the likely cause.

Incorrect

Excessive crankshaft end-play—movement along the crankshaft’s axis—can produce a knocking noise in a diesel engine. When the clutch pedal is pressed, the load on the crankshaft changes, which can temporarily reduce or eliminate the noise. While worn main bearings can also cause knocking, the fact that the noise disappears when the clutch is engaged more strongly suggests that excessive crankshaft end-play is the likely cause.

-

Question 49 of 56

49. Question

1 pointsIf you found an orange colored liquid under the front of the engine, what is that fluid?

Correct

If you notice an orange-colored liquid under the front of the engine, the most likely source is coolant. While coolant is often bright green, some manufacturers use orange, pink, or other colors to differentiate their specific formulations. Coolant plays a critical role in regulating engine temperature by circulating through the engine, radiator, and other cooling components. In contrast, automatic transmission fluid (ATF) is typically red, engine oil is brown or black, and windshield washer fluid is usually blue or clear. If you suspect a coolant leak, it’s important to have it inspected and repaired promptly, as running an engine without sufficient coolant can lead to severe overheating and major engine damage.

Incorrect

If you notice an orange-colored liquid under the front of the engine, the most likely source is coolant. While coolant is often bright green, some manufacturers use orange, pink, or other colors to differentiate their specific formulations. Coolant plays a critical role in regulating engine temperature by circulating through the engine, radiator, and other cooling components. In contrast, automatic transmission fluid (ATF) is typically red, engine oil is brown or black, and windshield washer fluid is usually blue or clear. If you suspect a coolant leak, it’s important to have it inspected and repaired promptly, as running an engine without sufficient coolant can lead to severe overheating and major engine damage.

-

Question 50 of 56

50. Question

1 pointsDiscussing engine valve seals, technician A wants to apply a light coat of engine oil to new oil seals and push them in. Meanwhile technician B thinks that the intake oil seal can be installed into the exhaust side or you can install the exhaust oil seal into the intake side because they are interchangeable. Who is CORRECT?

Correct

Technician A is correct. Applying a light coat of engine oil to new valve seals before installation is standard practice. This helps ensure proper lubrication during initial startup and prevents damage to the seals. It’s also essential to follow the manufacturer’s specifications, as installation procedures can vary between engine designs.

Technician B is incorrect. Intake and exhaust valve seals are not interchangeable. They are specifically designed to match the dimensions and requirements of their respective valve stems and guides. Using the wrong seal can lead to oil leaks and reduced engine performance.

Incorrect

Technician A is correct. Applying a light coat of engine oil to new valve seals before installation is standard practice. This helps ensure proper lubrication during initial startup and prevents damage to the seals. It’s also essential to follow the manufacturer’s specifications, as installation procedures can vary between engine designs.

Technician B is incorrect. Intake and exhaust valve seals are not interchangeable. They are specifically designed to match the dimensions and requirements of their respective valve stems and guides. Using the wrong seal can lead to oil leaks and reduced engine performance.

-

Question 51 of 56

51. Question

1 pointsWhat is the function of a brake caliper?

Correct

The brake caliper is a vital component of a vehicle’s braking system, responsible for engaging and controlling the brake pads. When the brake pedal is pressed, hydraulic pressure forces the caliper to squeeze the brake pads against the rotor. This contact generates friction, which slows the wheel’s rotation and brings the vehicle to a stop. In essence, the caliper initiates the braking process by activating the brake pads.

Incorrect

The brake caliper is a vital component of a vehicle’s braking system, responsible for engaging and controlling the brake pads. When the brake pedal is pressed, hydraulic pressure forces the caliper to squeeze the brake pads against the rotor. This contact generates friction, which slows the wheel’s rotation and brings the vehicle to a stop. In essence, the caliper initiates the braking process by activating the brake pads.

-

Question 52 of 56

52. Question

1 pointsWhat is the meaning of the brake warning light illuminated on the dashboard?

Correct

When the brake warning light appears on the dashboard, it usually signals a problem within the brake system. Common causes include low brake fluid, worn brake pads, a faulty master cylinder, or issues with the anti-lock braking system (ABS). Since the braking system is critical to vehicle safety, any warning should be investigated and resolved promptly to ensure safe operation.

Incorrect

When the brake warning light appears on the dashboard, it usually signals a problem within the brake system. Common causes include low brake fluid, worn brake pads, a faulty master cylinder, or issues with the anti-lock braking system (ABS). Since the braking system is critical to vehicle safety, any warning should be investigated and resolved promptly to ensure safe operation.

-

Question 53 of 56

53. Question

1 pointsA vehicle utilizing a HEUI fuel system exhibits difficulty starting at engine temperatures below 35°F (1.7°C). Technician A suggests that worn injectors may be the reason, while Technician B suggests that an open glow plug could be the cause. Which technician is CORRECT?

Correct

Technician A is correct. In a HEUI (Hydraulic Electronic Unit Injector) fuel system, worn injectors can cause hard starting at low engine temperatures. If the injectors fail to deliver fuel properly or produce an incorrect spray pattern, fuel atomization and combustion may be inadequate, making cold starts difficult.

Technician B is incorrect in directly linking an open glow plug to the HEUI system. While glow plugs assist with cold starting by heating the combustion chamber in diesel engines, they operate independently of the HEUI system. Although a faulty glow plug can contribute to starting issues in cold conditions, it is not directly related to the performance of the HEUI fuel system.

Incorrect

Technician A is correct. In a HEUI (Hydraulic Electronic Unit Injector) fuel system, worn injectors can cause hard starting at low engine temperatures. If the injectors fail to deliver fuel properly or produce an incorrect spray pattern, fuel atomization and combustion may be inadequate, making cold starts difficult.

Technician B is incorrect in directly linking an open glow plug to the HEUI system. While glow plugs assist with cold starting by heating the combustion chamber in diesel engines, they operate independently of the HEUI system. Although a faulty glow plug can contribute to starting issues in cold conditions, it is not directly related to the performance of the HEUI fuel system.

-

Question 54 of 56

54. Question

1 pointsRefurbishing the gasket surface of a diesel cylinder head will impact all dimensions EXCEPT

_________.Correct

Resurfacing the cylinder head gasket surface involves removing a small amount of material to ensure a smooth, flat surface for proper head gasket sealing. However, this process does not affect valve stem installed height. The valve stem installed height—measured from the valve spring seat to the tip of the valve stem when the valve is closed—is determined by factors such as valve length, valve seat depth, and valve spring seat position. Since resurfacing only alters the gasket mating surface, it does not directly impact these dimensions.

Incorrect

Resurfacing the cylinder head gasket surface involves removing a small amount of material to ensure a smooth, flat surface for proper head gasket sealing. However, this process does not affect valve stem installed height. The valve stem installed height—measured from the valve spring seat to the tip of the valve stem when the valve is closed—is determined by factors such as valve length, valve seat depth, and valve spring seat position. Since resurfacing only alters the gasket mating surface, it does not directly impact these dimensions.

-

Question 55 of 56

55. Question

1 pointsA client arrives with a vehicle to a mechanic, expressing concerns about its drivability. What initial steps should the mechanic take?

Correct

Gathering detailed information about the customer’s complaint is a critical first step in the diagnostic process. The technician should begin by interviewing the customer to gain a clear understanding of the issue. This ensures that all subsequent steps—such as checking diagnostic trouble codes, performing a visual inspection, or conducting a road test—are guided by accurate and relevant information.

Incorrect

Gathering detailed information about the customer’s complaint is a critical first step in the diagnostic process. The technician should begin by interviewing the customer to gain a clear understanding of the issue. This ensures that all subsequent steps—such as checking diagnostic trouble codes, performing a visual inspection, or conducting a road test—are guided by accurate and relevant information.

-

Question 56 of 56

56. Question

1 pointsWhich of the following will NOT happen when an oil filter becomes clogged?

Correct

The oil pump does not speed up when the oil filter becomes clogged. In fact, it may face increased resistance and operate less efficiently as it struggles to push oil through the restriction. Here’s why:

-

The oil pump is mechanically driven by the engine and its speed is directly tied to engine RPM, not the condition of the oil filter.

-

It’s designed to deliver a specific volume of oil based on engine speed, regardless of whether the filter is clean or clogged.

-

Increasing pump speed due to a clogged filter would risk generating excessive oil pressure, potentially damaging engine components.

When the oil filter is clogged, oil pressure can drop, engine temperature may rise, and internal wear increases—highlighting the importance of regular filter maintenance.

Incorrect

The oil pump does not speed up when the oil filter becomes clogged. In fact, it may face increased resistance and operate less efficiently as it struggles to push oil through the restriction. Here’s why:

-

The oil pump is mechanically driven by the engine and its speed is directly tied to engine RPM, not the condition of the oil filter.

-

It’s designed to deliver a specific volume of oil based on engine speed, regardless of whether the filter is clean or clogged.

-

Increasing pump speed due to a clogged filter would risk generating excessive oil pressure, potentially damaging engine components.

When the oil filter is clogged, oil pressure can drop, engine temperature may rise, and internal wear increases—highlighting the importance of regular filter maintenance.