The A2: Automatic Transmission covers key topics in automatic transmission and transaxle systems. It helps you prepare for the official exam by simulating real questions on diagnostics, components, and repair procedures. Ideal for building confidence and testing your knowledge.

Practice 2

Quiz-summary

0 of 60 questions completed

Questions:

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

Information

A2: Automatic Transmission

You have already completed the quiz before. Hence you can not start it again.

Quiz is loading...

You must sign in or sign up to start the quiz.

You have to finish following quiz, to start this quiz:

Results

0 of 60 questions answered correctly

Your time:

Time has elapsed

You have reached 0 of 0 points, (0)

| Average score |

|

| Your score |

|

Categories

- Not categorized 0%

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- Answered

- Review

-

Question 1 of 60

1. Question

1 pointsMetal flakes and shavings can be found at the bottom of a transmission’s oil pan. Which of the following is the source of this debris?

Correct

The most likely cause of metal flakes or shavings in a transmission’s oil pan is chipped gear teeth. Transmission gears are constantly engaging with one another, and over time, this friction can lead to wear, chipping, or breakage—resulting in metal debris collecting in the oil pan.

Although worn bands or clutches may also generate some metal particles, they typically do not produce the larger flakes or shavings associated with gear damage. Regardless of the source, the presence of metal debris in the oil pan is abnormal and should be promptly investigated to prevent further transmission damage.

Incorrect

The most likely cause of metal flakes or shavings in a transmission’s oil pan is chipped gear teeth. Transmission gears are constantly engaging with one another, and over time, this friction can lead to wear, chipping, or breakage—resulting in metal debris collecting in the oil pan.

Although worn bands or clutches may also generate some metal particles, they typically do not produce the larger flakes or shavings associated with gear damage. Regardless of the source, the presence of metal debris in the oil pan is abnormal and should be promptly investigated to prevent further transmission damage.

-

Question 2 of 60

2. Question

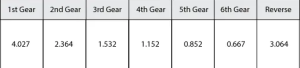

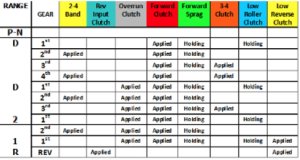

1 pointsDiagnostic instruments for shifting problems include transmission solenoid, clutches, and band charts. A vehicle does not move into first gear and does not have overdrive. View the provided chart to determine which of the following is CORRECT?

Correct

The issue could lie with either the solenoid or the electrical circuit. The Transmission Control Module (TCM) activates solenoid B to engage first and second gears.

Incorrect

The issue could lie with either the solenoid or the electrical circuit. The Transmission Control Module (TCM) activates solenoid B to engage first and second gears.

-

Question 3 of 60

3. Question

1 pointsDuring a stall test, the engine speed (RPM) is below the specified level. Technician A suggests that the transmission/transaxle might have insufficient fluid. Technician B suggests that the torque converter clutch could be slipping. Who is CORRECT?

Correct

If engine RPM is lower than specified during a stall test, it may indicate low transmission or transaxle fluid. Insufficient fluid can lead to reduced hydraulic pressure, causing the transmission to slip or fail to engage properly—resulting in decreased engine speed.

Technician B’s suggestion that a slipping torque converter clutch is to blame is incorrect in this case. A slipping torque converter clutch would usually cause higher, not lower, RPM during a stall test. Therefore, Technician B’s diagnosis does not apply to this situation.

Incorrect

If engine RPM is lower than specified during a stall test, it may indicate low transmission or transaxle fluid. Insufficient fluid can lead to reduced hydraulic pressure, causing the transmission to slip or fail to engage properly—resulting in decreased engine speed.

Technician B’s suggestion that a slipping torque converter clutch is to blame is incorrect in this case. A slipping torque converter clutch would usually cause higher, not lower, RPM during a stall test. Therefore, Technician B’s diagnosis does not apply to this situation.

-

Question 4 of 60

4. Question

1 pointsTechnician A believes that an unbalanced torque converter could lead to many vibration issues. But technician B thinks that vibration problems should be the result of a faulty output shaft. Who is CORRECT?

Correct

An unbalanced torque converter can definitely lead to vibration problems in a vehicle. Since the torque converter transfers power from the engine to the transmission, any imbalance can create engine vibrations that are felt throughout the vehicle. However, a damaged or worn output shaft can also cause similar issues. The output shaft delivers power from the transmission to the wheels, and if it’s faulty, it can result in noticeable vibrations during operation.

Incorrect

An unbalanced torque converter can definitely lead to vibration problems in a vehicle. Since the torque converter transfers power from the engine to the transmission, any imbalance can create engine vibrations that are felt throughout the vehicle. However, a damaged or worn output shaft can also cause similar issues. The output shaft delivers power from the transmission to the wheels, and if it’s faulty, it can result in noticeable vibrations during operation.

-

Question 5 of 60

5. Question

1 pointsIn neutral, a vehicle with an automatic transmission creeps forward. Which of the following is MOST LIKELY to be the cause of this condition?

Correct

The gear selector controls the transmission circuit through the manual valve, which is connected via the shift cable. This linkage is usually adjustable. If it’s misadjusted, the manual valve may direct line pressure into the wrong circuit.

As a result, the vehicle might move unexpectedly while in neutral, placing stress on the transmission’s clutch and potentially causing damage or overheating. To prevent this, inspect and properly adjust the shift cable and linkage. This adjustment is essential for safe operation. Always consult the manufacturer’s manual and check for applicable Technical Service Bulletins (TSBs) before making any changes.

Incorrect

The gear selector controls the transmission circuit through the manual valve, which is connected via the shift cable. This linkage is usually adjustable. If it’s misadjusted, the manual valve may direct line pressure into the wrong circuit.

As a result, the vehicle might move unexpectedly while in neutral, placing stress on the transmission’s clutch and potentially causing damage or overheating. To prevent this, inspect and properly adjust the shift cable and linkage. This adjustment is essential for safe operation. Always consult the manufacturer’s manual and check for applicable Technical Service Bulletins (TSBs) before making any changes.

-

Question 6 of 60

6. Question

1 pointsAccording to the provide chart, which gear ratio best represents overdrive?

Correct

Correct

The overdrive gear ratio is the one that produces the highest output shaft speed relative to engine speed. In the chart provided, the overdrive ratio is 0.852:1, meaning the output shaft turns once for every 0.852 rotations of the engine. Since this is the highest (numerically lowest) ratio in the chart, it best represents the overdrive gear.

Incorrect

The overdrive gear ratio is the one that produces the highest output shaft speed relative to engine speed. In the chart provided, the overdrive ratio is 0.852:1, meaning the output shaft turns once for every 0.852 rotations of the engine. Since this is the highest (numerically lowest) ratio in the chart, it best represents the overdrive gear.

-

Question 7 of 60

7. Question

1 pointsWhich is NOT correct about transmission removal and replacement?

Correct

Marking the front drive axles in relation to the front hubs is not a required step during transmission removal and replacement. While it’s important to handle the axles carefully to avoid damage, marking their position relative to the hubs is not a standard part of the procedure.

However, when removing the driveshaft, you should mark its position in relation to the differential flange. This ensures proper alignment during reinstallation and helps prevent driveline vibrations.

To safely remove the transmission, use an engine support fixture or other appropriate support to hold the engine in place. This prevents unnecessary strain on connected components and allows for smoother removal.

Additionally, always disconnect the negative battery cable before beginning any transmission work. This is a critical safety step to avoid electrical shorts and create a safer work environment.

Incorrect

Marking the front drive axles in relation to the front hubs is not a required step during transmission removal and replacement. While it’s important to handle the axles carefully to avoid damage, marking their position relative to the hubs is not a standard part of the procedure.

However, when removing the driveshaft, you should mark its position in relation to the differential flange. This ensures proper alignment during reinstallation and helps prevent driveline vibrations.

To safely remove the transmission, use an engine support fixture or other appropriate support to hold the engine in place. This prevents unnecessary strain on connected components and allows for smoother removal.

Additionally, always disconnect the negative battery cable before beginning any transmission work. This is a critical safety step to avoid electrical shorts and create a safer work environment.

-

Question 8 of 60

8. Question

1 pointsAfter an overhaul, the input shaft of an automatic transmission is binding and has no endplay. Technician A believes that installing the transmission and running the vehicle will fix the problem. Technician B suggests that a thinner selective washer may need to be installed to adjust the endplay of the input shaft. Who is CORRECT?

Correct

If the input shaft of an automatic transmission is binding and has no endplay after a rebuild, simply installing the transmission and operating the vehicle will not resolve the issue. The binding is likely due to incorrect assembly, improper clearance, or damaged components, and further inspection and repair are necessary.

Technician B’s suggestion that a thinner selective washer may be needed is valid. Selective washers are used to adjust input shaft endplay, and if the endplay is too tight, it can cause the shaft to bind, affecting transmission performance. Installing a thinner washer can restore proper endplay and help eliminate the binding issue.

Incorrect

If the input shaft of an automatic transmission is binding and has no endplay after a rebuild, simply installing the transmission and operating the vehicle will not resolve the issue. The binding is likely due to incorrect assembly, improper clearance, or damaged components, and further inspection and repair are necessary.

Technician B’s suggestion that a thinner selective washer may be needed is valid. Selective washers are used to adjust input shaft endplay, and if the endplay is too tight, it can cause the shaft to bind, affecting transmission performance. Installing a thinner washer can restore proper endplay and help eliminate the binding issue.

-

Question 9 of 60

9. Question

1 pointsThe dipstick tube is leaking transmission fluid. According to Technician A, this could be caused by overfilling the transmission. According to Technician B, this leak could be caused by aerated and foamy fluid. Who is CORRECT?

Correct

Overfilling the transmission can lead to excessive fluid pressure, which may force fluid out through the dipstick tube and cause a leak. An overly high fluid level can also cause the fluid to aerate and foam, increasing the likelihood of leakage from the dipstick tube.

Likewise, aerated or foamy fluid can reduce the transmission’s ability to lubricate and cool properly. This can result in overheating and potential damage, which may also lead to fluid leaks.

Therefore, both Technician A and Technician B could be correct. Further inspection is necessary to determine the exact cause of the transmission fluid leak.

Incorrect

Overfilling the transmission can lead to excessive fluid pressure, which may force fluid out through the dipstick tube and cause a leak. An overly high fluid level can also cause the fluid to aerate and foam, increasing the likelihood of leakage from the dipstick tube.

Likewise, aerated or foamy fluid can reduce the transmission’s ability to lubricate and cool properly. This can result in overheating and potential damage, which may also lead to fluid leaks.

Therefore, both Technician A and Technician B could be correct. Further inspection is necessary to determine the exact cause of the transmission fluid leak.

-

Question 10 of 60

10. Question

1 pointsWhich of the following will be identified by an automatic transmission pressure test?

Correct

A clogged transmission filter is one of the most common problems revealed during an automatic transmission pressure test. When the filter is dirty, it restricts the flow of hydraulic fluid, causing pressure to rise abnormally within the system. These pressure irregularities can be quickly identified at designated test points during the pressure test.

Incorrect

A clogged transmission filter is one of the most common problems revealed during an automatic transmission pressure test. When the filter is dirty, it restricts the flow of hydraulic fluid, causing pressure to rise abnormally within the system. These pressure irregularities can be quickly identified at designated test points during the pressure test.

-

Question 11 of 60

11. Question

1 pointsThe MIL is illuminated, and the transmission only works in third and reverse gears. Which of the following is MOST LIKELY to be the cause of this condition?

Correct

The most likely reason the MIL is on and the transmission only functions in third and reverse gears is that the vehicle has entered Limp Mode.

Limp Mode is a built-in safety feature in modern automatic transmissions designed to prevent further damage when a serious fault is detected. When the Transmission Control Module (TCM) identifies a problem that could harm the transmission, it restricts gear operation—usually to third and reverse—to allow the driver to safely reach a repair facility.

One of the most common triggers for Limp Mode is low line pressure, which can result from a clogged transmission filter, a failing pump, or a faulty pressure control solenoid. Low line pressure often leads to symptoms such as slipping, delayed engagement, or harsh shifting.

Although adaptive learning or high line pressure can cause shifting issues, they typically do not restrict the transmission to just third and reverse gears. For this reason, Limp Mode caused by low line pressure is the most likely cause of the condition described.

Incorrect

The most likely reason the MIL is on and the transmission only functions in third and reverse gears is that the vehicle has entered Limp Mode.

Limp Mode is a built-in safety feature in modern automatic transmissions designed to prevent further damage when a serious fault is detected. When the Transmission Control Module (TCM) identifies a problem that could harm the transmission, it restricts gear operation—usually to third and reverse—to allow the driver to safely reach a repair facility.

One of the most common triggers for Limp Mode is low line pressure, which can result from a clogged transmission filter, a failing pump, or a faulty pressure control solenoid. Low line pressure often leads to symptoms such as slipping, delayed engagement, or harsh shifting.

Although adaptive learning or high line pressure can cause shifting issues, they typically do not restrict the transmission to just third and reverse gears. For this reason, Limp Mode caused by low line pressure is the most likely cause of the condition described.

-

Question 12 of 60

12. Question

1 pointsThe diagnostic symptom chart is being utilized to identify a peculiar noise while driving in an electronically controlled 5-speed automatic rear-wheel drive (RWD) transmission. Technician A suggests that the control valve might be the cause and that it requires a procedure performed off the vehicle. On the other hand, Technician B proposes that the oil pump assembly could be the culprit and also necessitates an off-vehicle procedure. Which technician is ACCURATE?

Correct

Technician B believes the noise may be coming from the oil pump assembly and recommends an off-vehicle inspection. The oil pump is responsible for circulating transmission fluid and maintaining the hydraulic pressure needed for proper operation. If it’s damaged or malfunctioning, it can produce unusual noises within the transmission.

Technician A suggests the control valve could be the source of the noise and also requires off-vehicle service. While the control valve regulates fluid flow and direction, it is less likely to cause distinct noises compared to a faulty oil pump. Therefore, Technician B’s diagnosis is more plausible in this scenario.

Incorrect

Technician B believes the noise may be coming from the oil pump assembly and recommends an off-vehicle inspection. The oil pump is responsible for circulating transmission fluid and maintaining the hydraulic pressure needed for proper operation. If it’s damaged or malfunctioning, it can produce unusual noises within the transmission.

Technician A suggests the control valve could be the source of the noise and also requires off-vehicle service. While the control valve regulates fluid flow and direction, it is less likely to cause distinct noises compared to a faulty oil pump. Therefore, Technician B’s diagnosis is more plausible in this scenario.

-

Question 13 of 60

13. Question

1 pointsWhich of the following tests is NOT used for the electronically controlled automatic transmission preliminary diagnostics?

Correct

The flex plate check is not part of the preliminary diagnostics for an electronically controlled automatic transmission. In contrast, tests such as the fluid check, line pressure test, and stall test are commonly used to identify issues within these systems.

The flex plate, which connects the engine to the transmission, is a mechanical component and not part of the electronic control system. As a result, it is not typically included in the initial diagnostic procedures for electronically controlled transmissions.

Incorrect

The flex plate check is not part of the preliminary diagnostics for an electronically controlled automatic transmission. In contrast, tests such as the fluid check, line pressure test, and stall test are commonly used to identify issues within these systems.

The flex plate, which connects the engine to the transmission, is a mechanical component and not part of the electronic control system. As a result, it is not typically included in the initial diagnostic procedures for electronically controlled transmissions.

-

Question 14 of 60

14. Question

1 pointsWhich tool is utilized for measuring ring gear backlash after replacing the final drive assembly of a transaxle?

Correct

A dial indicator is the tool most commonly used to measure ring gear backlash. It provides precise measurements of small movements, making it ideal for checking clearances and tolerances in automotive applications.

The other tools listed serve different purposes: a straightedge and feeler gauge are used to measure flatness or small gaps, an inch-pound torque wrench is for checking torque values, and an outside micrometer measures the diameter of round components. These tools are not typically used for measuring ring gear backlash.

Incorrect

A dial indicator is the tool most commonly used to measure ring gear backlash. It provides precise measurements of small movements, making it ideal for checking clearances and tolerances in automotive applications.

The other tools listed serve different purposes: a straightedge and feeler gauge are used to measure flatness or small gaps, an inch-pound torque wrench is for checking torque values, and an outside micrometer measures the diameter of round components. These tools are not typically used for measuring ring gear backlash.

-

Question 15 of 60

15. Question

1 pointsOnly when turning corners does an automatic transaxle slip. Which of the following is the MOST LIKELY reason?

Correct

Automatic transaxles depend on the proper amount of transmission fluid to lubricate and cool internal components such as clutches, bands, and gears. Low fluid levels can cause a drop in hydraulic pressure, leading to slipping or inconsistent engagement.

During cornering, centrifugal force can cause the fluid to shift within the transaxle. If the fluid level is already low, this movement may result in a temporary loss of pressure or poor lubrication, causing the clutches or bands to slip. This often presents as hesitation or slipping while turning.

Incorrect

Automatic transaxles depend on the proper amount of transmission fluid to lubricate and cool internal components such as clutches, bands, and gears. Low fluid levels can cause a drop in hydraulic pressure, leading to slipping or inconsistent engagement.

During cornering, centrifugal force can cause the fluid to shift within the transaxle. If the fluid level is already low, this movement may result in a temporary loss of pressure or poor lubrication, causing the clutches or bands to slip. This often presents as hesitation or slipping while turning.

-

Question 16 of 60

16. Question

1 pointsAccording to Technician A, pink milky transmission fluid is caused by a leaking transmission oil cooler. According to Technician B, it is caused by heat and oxidation. Who is CORRECT?

Correct

Milky fluid in the transmission cooler is a clear sign of contamination, typically caused by a mix of transmission fluid (ATF) and engine coolant. This cross-contamination occurs when a leak develops within the transmission cooler—a heat exchanger designed to keep the transmission fluid at a safe operating temperature. The cooler is usually located inside the radiator or in a separate unit, with coolant and transmission fluid flowing through isolated chambers.

If the internal barrier fails, coolant can enter the ATF system. Because coolant contains water and ethylene glycol—both hygroscopic substances—it attracts moisture and reacts with the oil in the transmission fluid, forming a milky, emulsified mixture. This contamination can severely affect transmission performance and should be addressed immediately.

Incorrect

Milky fluid in the transmission cooler is a clear sign of contamination, typically caused by a mix of transmission fluid (ATF) and engine coolant. This cross-contamination occurs when a leak develops within the transmission cooler—a heat exchanger designed to keep the transmission fluid at a safe operating temperature. The cooler is usually located inside the radiator or in a separate unit, with coolant and transmission fluid flowing through isolated chambers.

If the internal barrier fails, coolant can enter the ATF system. Because coolant contains water and ethylene glycol—both hygroscopic substances—it attracts moisture and reacts with the oil in the transmission fluid, forming a milky, emulsified mixture. This contamination can severely affect transmission performance and should be addressed immediately.

-

Question 17 of 60

17. Question

1 pointsThe transmission oil pump, according to Technician A, is the source of all fluid flow in an automatic transmission. According to Technician B, hydraulic flow charts show the flow of hydraulic fluid via the transmission’s solenoids, valves, and oil circuits. Who is CORRECT

Correct

Both technicians are correct. Technician A is right in stating that the transmission oil pump is the source of all fluid flow in an automatic transmission. It generates the hydraulic pressure needed to circulate fluid through the transmission and its internal circuits.

Technician B is also correct. Hydraulic flow charts illustrate how fluid moves through solenoids, valves, and various oil circuits within the transmission. These charts are valuable diagnostic tools that help technicians pinpoint issues within the hydraulic system.

Incorrect

Both technicians are correct. Technician A is right in stating that the transmission oil pump is the source of all fluid flow in an automatic transmission. It generates the hydraulic pressure needed to circulate fluid through the transmission and its internal circuits.

Technician B is also correct. Hydraulic flow charts illustrate how fluid moves through solenoids, valves, and various oil circuits within the transmission. These charts are valuable diagnostic tools that help technicians pinpoint issues within the hydraulic system.

-

Question 18 of 60

18. Question

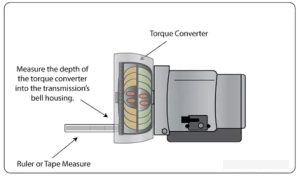

1 pointsWhen it comes to removing a torque converter from an automatic transmission, the technician should

_____________.Correct

When removing a torque converter from an automatic transmission, the technician should carefully inspect the converter’s hub for any signs of damage, such as discoloration, nicks, scratches, or burrs. These issues may point to underlying problems with either the torque converter or the transmission. It’s also important to measure how deep the torque converter sits within the transmission’s bell housing before removal. This measurement helps ensure correct alignment and installation during reassembly.

Incorrect

When removing a torque converter from an automatic transmission, the technician should carefully inspect the converter’s hub for any signs of damage, such as discoloration, nicks, scratches, or burrs. These issues may point to underlying problems with either the torque converter or the transmission. It’s also important to measure how deep the torque converter sits within the transmission’s bell housing before removal. This measurement helps ensure correct alignment and installation during reassembly.

-

Question 19 of 60

19. Question

1 pointsWhich of the following sensors directly influences the performance of both the engine and the automatic transmission?

Correct

The MAP (Manifold Absolute Pressure) sensor monitors the pressure within the intake manifold to provide the engine control unit (ECU) with data about engine load. This information is essential for adjusting the fuel-to-air ratio, ignition timing, and transmission shift points. By accurately reporting engine load, the MAP sensor helps optimize both engine performance and transmission response.

The MAF (Mass Air Flow) sensor measures the amount of air entering the engine, allowing the ECU to calculate the precise amount of fuel needed for efficient combustion. Proper fuel metering is critical for maintaining engine performance, and the transmission adjusts its shifting patterns based on this output.

The TPS (Throttle Position Sensor) tracks the position of the throttle plate, reflecting the driver’s acceleration input. The ECU uses this signal to fine-tune fuel injection and ignition timing, while the Transmission Control Module (TCM) relies on it to determine appropriate shift points and adapt transmission behavior to match driving conditions.

Incorrect

The MAP (Manifold Absolute Pressure) sensor monitors the pressure within the intake manifold to provide the engine control unit (ECU) with data about engine load. This information is essential for adjusting the fuel-to-air ratio, ignition timing, and transmission shift points. By accurately reporting engine load, the MAP sensor helps optimize both engine performance and transmission response.

The MAF (Mass Air Flow) sensor measures the amount of air entering the engine, allowing the ECU to calculate the precise amount of fuel needed for efficient combustion. Proper fuel metering is critical for maintaining engine performance, and the transmission adjusts its shifting patterns based on this output.

The TPS (Throttle Position Sensor) tracks the position of the throttle plate, reflecting the driver’s acceleration input. The ECU uses this signal to fine-tune fuel injection and ignition timing, while the Transmission Control Module (TCM) relies on it to determine appropriate shift points and adapt transmission behavior to match driving conditions.

-

Question 20 of 60

20. Question

1 pointsAn automatic transmission will not leave PARK. According to Technician A, this condition is caused by a malfunctioning shift interlock solenoid. According to Technician B, this could be due to a defective brake switch. Who is CORRECT?

Correct

A faulty shift interlock solenoid is a common reason why an automatic transmission won’t shift out of PARK. This solenoid is controlled by the brake pedal and prevents the shifter from moving unless the brake is pressed. If the solenoid fails, it may not release the shifter even when the brake pedal is properly engaged.

However, a malfunctioning brake switch can also be the culprit. The brake switch sends the signal to activate the shift interlock solenoid when the brake pedal is pressed. If the switch is defective, it may fail to send this signal, keeping the shifter locked in PARK.

Incorrect

A faulty shift interlock solenoid is a common reason why an automatic transmission won’t shift out of PARK. This solenoid is controlled by the brake pedal and prevents the shifter from moving unless the brake is pressed. If the solenoid fails, it may not release the shifter even when the brake pedal is properly engaged.

However, a malfunctioning brake switch can also be the culprit. The brake switch sends the signal to activate the shift interlock solenoid when the brake pedal is pressed. If the switch is defective, it may fail to send this signal, keeping the shifter locked in PARK.

-

Question 21 of 60

21. Question

1 pointsTechnician A states that the turbine speed and the impeller speed become equal when the torque converter’s lockup clutch engages, while Technician B claims that the engagement of the lockup clutch occurs during the coupling phase of the torque converter. Who is CORRECT?

Correct

Both Technician A and Technician B are partially correct.

Technician A is right that when the torque converter’s lockup clutch engages, the turbine and impeller rotate at the same speed. This occurs because the lockup clutch eliminates the fluid coupling by creating a direct mechanical connection between the two components.

Technician B is also correct in stating that the lockup clutch engages during the coupling phase. In this phase, the impeller and turbine are already closely matched in speed due to fluid coupling. Once certain driving conditions are met—typically at higher speeds—the lockup clutch engages to eliminate slippage and improve efficiency.

Incorrect

Both Technician A and Technician B are partially correct.

Technician A is right that when the torque converter’s lockup clutch engages, the turbine and impeller rotate at the same speed. This occurs because the lockup clutch eliminates the fluid coupling by creating a direct mechanical connection between the two components.

Technician B is also correct in stating that the lockup clutch engages during the coupling phase. In this phase, the impeller and turbine are already closely matched in speed due to fluid coupling. Once certain driving conditions are met—typically at higher speeds—the lockup clutch engages to eliminate slippage and improve efficiency.

-

Question 22 of 60

22. Question

1 pointsAccording to Technician A, the EPC (electronic pressure control) system adjusts line pressure based on engine speed and torque. According to Technician B, the EPC system may contain a variable force solenoid. Who is CORRECT?

Correct

Both Technician A and Technician B are correct.

The Electronic Pressure Control (EPC) system in an automatic transmission uses electronic signals to regulate hydraulic pressure. It adjusts line pressure based on factors like engine speed and torque, ensuring the correct amount of pressure is applied to clutches and bands for smooth and precise gear shifts.

This system often includes a variable force solenoid, which is controlled by the Transmission Control Module (TCM). The solenoid modulates the hydraulic pressure by adjusting the force on the pressure control valve, allowing the EPC system to maintain optimal line pressure throughout various driving conditions.

Incorrect

Both Technician A and Technician B are correct.

The Electronic Pressure Control (EPC) system in an automatic transmission uses electronic signals to regulate hydraulic pressure. It adjusts line pressure based on factors like engine speed and torque, ensuring the correct amount of pressure is applied to clutches and bands for smooth and precise gear shifts.

This system often includes a variable force solenoid, which is controlled by the Transmission Control Module (TCM). The solenoid modulates the hydraulic pressure by adjusting the force on the pressure control valve, allowing the EPC system to maintain optimal line pressure throughout various driving conditions.

-

Question 23 of 60

23. Question

1 pointsThere is a leak in the front seal of the transmission oil pump, and the pump bushing is deteriorated. Technician A suggests that loose flexplate bolts could be the cause of this problem, while Technician B believes that a misaligned transmission bellhousing is responsible for the wear. Who is CORRECT?

Correct

The transmission oil pump circulates fluid throughout the automatic transmission, and its pump bushing supports the input shaft that links the torque converter to the transmission. If the pump’s front seal is leaking and the bushing is worn, transmission fluid may escape, leading to a drop in hydraulic pressure. This can result in slipping or failure to engage gears properly.

Technician A suggests that loose flexplate bolts could be the cause. Since the flexplate connects the engine to the torque converter and also mounts the starter motor, loose bolts can cause excessive movement. This movement may stress the input shaft, leading to wear on the pump bushing and front seal.

Technician B attributes the issue to a misaligned transmission bellhousing. The bellhousing ensures proper alignment between the engine, torque converter, and transmission input shaft. If misaligned, it can offset the input shaft, accelerating wear on the pump bushing and front seal.

Therefore, both Technician A and Technician B may be correct in identifying contributing factors to the problem.

Incorrect

The transmission oil pump circulates fluid throughout the automatic transmission, and its pump bushing supports the input shaft that links the torque converter to the transmission. If the pump’s front seal is leaking and the bushing is worn, transmission fluid may escape, leading to a drop in hydraulic pressure. This can result in slipping or failure to engage gears properly.

Technician A suggests that loose flexplate bolts could be the cause. Since the flexplate connects the engine to the torque converter and also mounts the starter motor, loose bolts can cause excessive movement. This movement may stress the input shaft, leading to wear on the pump bushing and front seal.

Technician B attributes the issue to a misaligned transmission bellhousing. The bellhousing ensures proper alignment between the engine, torque converter, and transmission input shaft. If misaligned, it can offset the input shaft, accelerating wear on the pump bushing and front seal.

Therefore, both Technician A and Technician B may be correct in identifying contributing factors to the problem.

-

Question 24 of 60

24. Question

1 pointsThe torque converter clutch on a transaxle is not engaged. According to Technician A, this could be caused by a malfunctioning TFT sensor. According to Technician B, this issue is caused by a faulty ECT sensor. Who is CORRECT?

Correct

Both technicians could be correct, as both the Transmission Fluid Temperature (TFT) sensor and the Engine Coolant Temperature (ECT) sensor can influence torque converter clutch operation. The TFT sensor sends data to the Transmission Control Module (TCM) regarding fluid temperature, which helps determine when the torque converter clutch should engage. Similarly, the ECT sensor provides the Engine Control Module (ECM) with engine coolant temperature information, which can impact both engine and transmission performance.

Given that both sensors play a role, further diagnostic testing is needed to identify the exact cause of the issue.

Incorrect

Both technicians could be correct, as both the Transmission Fluid Temperature (TFT) sensor and the Engine Coolant Temperature (ECT) sensor can influence torque converter clutch operation. The TFT sensor sends data to the Transmission Control Module (TCM) regarding fluid temperature, which helps determine when the torque converter clutch should engage. Similarly, the ECT sensor provides the Engine Control Module (ECM) with engine coolant temperature information, which can impact both engine and transmission performance.

Given that both sensors play a role, further diagnostic testing is needed to identify the exact cause of the issue.

-

Question 25 of 60

25. Question

1 pointsThe electrical item in the illustration represents

_________.Correct

A Single Pole Double Throw (SPDT) electromechanical relay is an electrical switch made up of a coil, an armature, and a set of contacts. It features one input terminal, known as the common terminal (COM), and two output terminals: one normally open (NO) and one normally closed (NC).

Incorrect

A Single Pole Double Throw (SPDT) electromechanical relay is an electrical switch made up of a coil, an armature, and a set of contacts. It features one input terminal, known as the common terminal (COM), and two output terminals: one normally open (NO) and one normally closed (NC).

-

Question 26 of 60

26. Question

1 points26. Which of the following options is NOT the industry-standard methods used to reprogram the EEPROM?

Correct

Direct programming involves connecting the EEPROM directly to a programmer, which transfers data straight to the memory chip.

Off-board programming requires removing the EEPROM from the circuit board and programming it separately with a dedicated device.

Remote programming allows the EEPROM to be reprogrammed while still installed on the board, using a specialized tool that connects remotely.

“Indirect programming” is not a standard method used for reprogramming EEPROMs.

Incorrect

Direct programming involves connecting the EEPROM directly to a programmer, which transfers data straight to the memory chip.

Off-board programming requires removing the EEPROM from the circuit board and programming it separately with a dedicated device.

Remote programming allows the EEPROM to be reprogrammed while still installed on the board, using a specialized tool that connects remotely.

“Indirect programming” is not a standard method used for reprogramming EEPROMs.

-

Question 27 of 60

27. Question

1 pointsTechnician A claims that the input shaft of an automatic transmission powers the vehicle speed sensor, while Technician B states that the parking pawl locks the transmission into Park by engaging the input shaft. Which technician is CORRECT?

Correct

Both the vehicle speed sensor and the parking pawl are connected to the output shaft of an automatic transmission. The vehicle speed sensor is driven by the output shaft to measure the vehicle’s speed, while the parking pawl locks the output shaft in place to hold the transmission in Park.

Incorrect

Both the vehicle speed sensor and the parking pawl are connected to the output shaft of an automatic transmission. The vehicle speed sensor is driven by the output shaft to measure the vehicle’s speed, while the parking pawl locks the output shaft in place to hold the transmission in Park.

-

Question 28 of 60

28. Question

1 pointsLow pressure is detected using the line pressure test when idling in all ranges with an electronically controlled automatic transmission. What the MOST LIKELY be the reason?

Correct

The most likely cause of low line pressure at idle in all ranges in an electronically controlled automatic transmission is a faulty oil pump pressure regulator. This component controls the output of the oil pump to maintain proper hydraulic pressure throughout the transmission. If it malfunctions, it can lead to consistently low pressure, resulting in shifting problems and reduced transmission performance.

Although issues such as a faulty ATF temperature sensor, an improperly adjusted throttle position (TP) sensor, or an open circuit in the dropping resistor can affect transmission performance, they are less likely to cause low pressure at idle across all ranges. Accurate diagnosis is essential to identify the root cause and ensure the correct repair.

Incorrect

The most likely cause of low line pressure at idle in all ranges in an electronically controlled automatic transmission is a faulty oil pump pressure regulator. This component controls the output of the oil pump to maintain proper hydraulic pressure throughout the transmission. If it malfunctions, it can lead to consistently low pressure, resulting in shifting problems and reduced transmission performance.

Although issues such as a faulty ATF temperature sensor, an improperly adjusted throttle position (TP) sensor, or an open circuit in the dropping resistor can affect transmission performance, they are less likely to cause low pressure at idle across all ranges. Accurate diagnosis is essential to identify the root cause and ensure the correct repair.

-

Question 29 of 60

29. Question

1 pointsA car equipped with an automatic three-speed synchronous transmission slips when shifting from first to second gear in drive. Technician A suggests that slipping and engine flare can occur in synchronous transmissions due to incorrect shift timing. Technician B, on the other hand, attributes the slipping to the early application of the intermediate band. Who is CORRECT?

Correct

Slipping and engine flare in synchronous transmissions can result from incorrect shift timing. These transmissions use synchronizers to match gear speeds during shifts. When shift timing is off—such as the synchronizers engaging too slowly or at the wrong moment—proper gear engagement may not occur. This incomplete engagement leads to slipping, where power isn’t fully transferred, causing the engine to rev higher (engine flare) without a corresponding increase in vehicle speed.

Incorrect

Slipping and engine flare in synchronous transmissions can result from incorrect shift timing. These transmissions use synchronizers to match gear speeds during shifts. When shift timing is off—such as the synchronizers engaging too slowly or at the wrong moment—proper gear engagement may not occur. This incomplete engagement leads to slipping, where power isn’t fully transferred, causing the engine to rev higher (engine flare) without a corresponding increase in vehicle speed.

-

Question 30 of 60

30. Question

1 pointsWhich of the following is the LEAST probable cause of delayed engagement when shifting from Park to Drive or Reverse on an automatic transmission?

Correct

An “open shift interlock solenoid” is less likely to cause delayed engagement when shifting from Park to Drive or Reverse in an automatic transmission. The shift interlock solenoid serves as a safety mechanism that prevents the shifter from moving out of Park unless the brake pedal is pressed. If it fails, it typically prevents the shifter from moving at all, rather than causing a delay in gear engagement.

In contrast, delayed engagement is more commonly caused by issues such as a clogged transmission oil filter, low hydraulic pressure, or oil pump starvation—factors that directly affect the transmission’s ability to engage gears promptly.

Incorrect

An “open shift interlock solenoid” is less likely to cause delayed engagement when shifting from Park to Drive or Reverse in an automatic transmission. The shift interlock solenoid serves as a safety mechanism that prevents the shifter from moving out of Park unless the brake pedal is pressed. If it fails, it typically prevents the shifter from moving at all, rather than causing a delay in gear engagement.

In contrast, delayed engagement is more commonly caused by issues such as a clogged transmission oil filter, low hydraulic pressure, or oil pump starvation—factors that directly affect the transmission’s ability to engage gears promptly.

-

Question 31 of 60

31. Question

1 pointsYou plan to diagnose a RWD, electronically controlled 5-speed automatic transmission that has an unusual noise while driving with your diagnostic symptom chart. The technician A believes that the oil pump assembly needs an off-vehicle procedure to address the issue. But technician B states it is the control valve which leads to the issue, so that it is necessary to take an off-vehicle procedure. Who is CORRECT?

Correct

Technician B is correct in identifying the control valve as the likely source of the issue, and diagnosing or repairing it typically requires removing the transmission—making it an off-vehicle procedure. In contrast, Technician A’s claim that the oil pump assembly also requires an off-vehicle procedure is incorrect.

The oil pump assembly is located inside the transmission and can often be accessed and removed without fully removing the transmission from the vehicle. This makes it an on-vehicle procedure. On the other hand, the control valve is part of the valve body, which generally requires transmission removal for proper access—making it an off-vehicle task.

Therefore, if a technician suspects the oil pump assembly is causing the problem, it can be inspected and serviced more easily without removing the transmission, saving time and effort compared to addressing issues with the control valve.

Incorrect

Technician B is correct in identifying the control valve as the likely source of the issue, and diagnosing or repairing it typically requires removing the transmission—making it an off-vehicle procedure. In contrast, Technician A’s claim that the oil pump assembly also requires an off-vehicle procedure is incorrect.

The oil pump assembly is located inside the transmission and can often be accessed and removed without fully removing the transmission from the vehicle. This makes it an on-vehicle procedure. On the other hand, the control valve is part of the valve body, which generally requires transmission removal for proper access—making it an off-vehicle task.

Therefore, if a technician suspects the oil pump assembly is causing the problem, it can be inspected and serviced more easily without removing the transmission, saving time and effort compared to addressing issues with the control valve.

-

Question 32 of 60

32. Question

1 pointsIf you experience a “shock” while shifting from Neutral to Drive when driving an electronically controlled 4-speed automatic transaxle. Which of these parts needs an off-vehicle repair first?Control valve assembly.Correct

When shifting from Neutral to Drive, the forward clutch engages to connect the transmission’s input shaft to the output shaft, enabling forward movement of the vehicle.

If the forward clutch has worn or damaged friction plates, or if the apply piston is malfunctioning, it can cause a harsh or abrupt engagement when shifting into Drive. This results in the noticeable “shock” or jolt sensation experienced during the shift.

Resolving this issue requires an off-vehicle repair. The transmission must be disassembled to inspect the forward clutch components for wear or damage. Depending on the findings, the clutch may need to be repaired or replaced, along with related parts such as the apply piston or seals.

Incorrect

When shifting from Neutral to Drive, the forward clutch engages to connect the transmission’s input shaft to the output shaft, enabling forward movement of the vehicle.

If the forward clutch has worn or damaged friction plates, or if the apply piston is malfunctioning, it can cause a harsh or abrupt engagement when shifting into Drive. This results in the noticeable “shock” or jolt sensation experienced during the shift.

Resolving this issue requires an off-vehicle repair. The transmission must be disassembled to inspect the forward clutch components for wear or damage. Depending on the findings, the clutch may need to be repaired or replaced, along with related parts such as the apply piston or seals.

-

Question 33 of 60

33. Question

1 pointsTechnician A stated that the seat for ball-type check valves is situated on the valve body separator plate, while Technician B explained that these valves are utilized in hydraulic circuits of valve bodies to enable fluid flow in a single direction. Who is CORRECT?Technician A.Correct

Both Technician A and Technician B are correct.

Ball-type check valves are commonly used in valve body hydraulic circuits to allow one-way fluid flow. These valves typically feature a small ball that rests in a seat, permitting fluid to pass in one direction while blocking flow in the opposite direction.

Technician A is also correct in stating that the seat for these ball-type check valves is often located on the valve body separator plate. This thin metal plate sits between the valve body and the transmission case, and it contains passages that route hydraulic fluid to various components within the valve body.

Incorrect

Both Technician A and Technician B are correct.

Ball-type check valves are commonly used in valve body hydraulic circuits to allow one-way fluid flow. These valves typically feature a small ball that rests in a seat, permitting fluid to pass in one direction while blocking flow in the opposite direction.

Technician A is also correct in stating that the seat for these ball-type check valves is often located on the valve body separator plate. This thin metal plate sits between the valve body and the transmission case, and it contains passages that route hydraulic fluid to various components within the valve body.

-

Question 34 of 60

34. Question

1 pointsWhich of the following influences the proportion of a transmission’s shift points to vehicle speed?

Correct

The governor typically controls how transmission shift points relate to vehicle speed. It monitors the output shaft speed—either mechanically or electronically—and signals the transmission control module when the vehicle reaches specific speeds to initiate gear shifts.

In contrast, the throttle valve regulates the air-fuel mixture entering the engine, affecting engine speed but not directly determining shift points based on vehicle speed. In an automatic transmission, throttle pressure generally corresponds to engine load, which reflects the vehicle’s overall load but does not serve as the primary input for shift timing related to speed.

Incorrect

The governor typically controls how transmission shift points relate to vehicle speed. It monitors the output shaft speed—either mechanically or electronically—and signals the transmission control module when the vehicle reaches specific speeds to initiate gear shifts.

In contrast, the throttle valve regulates the air-fuel mixture entering the engine, affecting engine speed but not directly determining shift points based on vehicle speed. In an automatic transmission, throttle pressure generally corresponds to engine load, which reflects the vehicle’s overall load but does not serve as the primary input for shift timing related to speed.

-

Question 35 of 60

35. Question

1 pointsWhen shifting into third gear, a three-speed automatic transmission makes a whining noise that goes away. This condition is MOST likely caused by

_________.Correct

If a three-speed automatic transmission produces a whining noise that stops after shifting into third gear, the most likely cause is an issue with the planetary gear set.

The planetary gear set is a critical component that enables various gear ratios and torque multiplication. It includes sun gears, planet gears, and a ring gear, all working together in a precise arrangement to deliver different speeds and torque levels.

Worn or damaged gears within this assembly can generate abnormal noises during operation. The fact that the whining noise disappears in third gear suggests the issue is tied to gear interactions used only in the lower ranges, indicating a specific problem within the planetary gear set.

Incorrect

If a three-speed automatic transmission produces a whining noise that stops after shifting into third gear, the most likely cause is an issue with the planetary gear set.

The planetary gear set is a critical component that enables various gear ratios and torque multiplication. It includes sun gears, planet gears, and a ring gear, all working together in a precise arrangement to deliver different speeds and torque levels.

Worn or damaged gears within this assembly can generate abnormal noises during operation. The fact that the whining noise disappears in third gear suggests the issue is tied to gear interactions used only in the lower ranges, indicating a specific problem within the planetary gear set.

-

Question 36 of 60

36. Question

1 pointsA dipstick is not present in an automatic transmission. No transmission fluid is noticed leaking from the outlet after bringing the transmission to operating temperature and removing the plug. According to Technician A, this is typical, and the fluid level is correct. According to Technician B, this suggests an overheated transmission. Who is CORRECT?

Correct

Neither Technician A nor Technician B is correct.

While many automatic transmissions use a dipstick to check fluid levels, some newer or sealed transmissions require specialized procedures and tools to measure fluid accurately. The absence of a dipstick does not indicate a problem—it simply reflects the design of that specific transmission model.

If, after bringing the transmission to operating temperature and removing the inspection plug, no fluid leaks from the outlet, it may indicate that the fluid level is correct for that system. However, it’s essential to consult the manufacturer’s service manual to confirm the correct procedure and specifications for checking fluid levels.

Additionally, the lack of fluid leakage does not necessarily mean the transmission is overheating. Overheating can result from various issues such as clogged fluid passages, a faulty cooling system, or internal transmission problems. To accurately determine if the transmission is overheating, the fluid temperature must be measured and compared to the manufacturer’s recommended operating range.

Incorrect

Neither Technician A nor Technician B is correct.

While many automatic transmissions use a dipstick to check fluid levels, some newer or sealed transmissions require specialized procedures and tools to measure fluid accurately. The absence of a dipstick does not indicate a problem—it simply reflects the design of that specific transmission model.

If, after bringing the transmission to operating temperature and removing the inspection plug, no fluid leaks from the outlet, it may indicate that the fluid level is correct for that system. However, it’s essential to consult the manufacturer’s service manual to confirm the correct procedure and specifications for checking fluid levels.

Additionally, the lack of fluid leakage does not necessarily mean the transmission is overheating. Overheating can result from various issues such as clogged fluid passages, a faulty cooling system, or internal transmission problems. To accurately determine if the transmission is overheating, the fluid temperature must be measured and compared to the manufacturer’s recommended operating range.

-

Question 37 of 60

37. Question

1 pointsA torque converter’s stator

_________.Correct

The stator in a torque converter is equipped with a one-way clutch that allows it to rotate freely in one direction while preventing rotation in the opposite direction. Positioned between the impeller and turbine, the stator’s main role is to redirect transmission fluid as it exits the turbine and returns to the impeller. This redirection significantly enhances torque multiplication and overall efficiency.

The one-way clutch enables the stator to spin when it supports fluid flow and torque multiplication but locks it in place when its rotation would create drag, ensuring optimal performance of the torque converter.

Incorrect

The stator in a torque converter is equipped with a one-way clutch that allows it to rotate freely in one direction while preventing rotation in the opposite direction. Positioned between the impeller and turbine, the stator’s main role is to redirect transmission fluid as it exits the turbine and returns to the impeller. This redirection significantly enhances torque multiplication and overall efficiency.

The one-way clutch enables the stator to spin when it supports fluid flow and torque multiplication but locks it in place when its rotation would create drag, ensuring optimal performance of the torque converter.

-

Question 38 of 60

38. Question

1 pointsA planetary gearset with an automated transmission is being tested for harsh shifting. Which of the following could be the reason?

Correct

All of the listed factors can contribute to harsh shifting in a planetary gearset with an automated transmission.

A faulty Electronic Pressure Control (EPC) solenoid can lead to harsh shifts by misregulating the hydraulic pressure needed for smooth gear changes. If the solenoid malfunctions, it may cause the transmission to shift too aggressively or inconsistently.

Similarly, a sticking pressure regulating valve can disrupt proper pressure control within the system. If the valve becomes stuck, it can prevent the transmission from maintaining the correct pressure, resulting in abrupt or delayed shifts.

Contaminated or degraded transmission fluid is another common cause. As fluid ages, it can accumulate debris and lose its effectiveness, leading to poor lubrication and hydraulic performance—both of which contribute to harsh or erratic shifting.

Incorrect

All of the listed factors can contribute to harsh shifting in a planetary gearset with an automated transmission.

A faulty Electronic Pressure Control (EPC) solenoid can lead to harsh shifts by misregulating the hydraulic pressure needed for smooth gear changes. If the solenoid malfunctions, it may cause the transmission to shift too aggressively or inconsistently.

Similarly, a sticking pressure regulating valve can disrupt proper pressure control within the system. If the valve becomes stuck, it can prevent the transmission from maintaining the correct pressure, resulting in abrupt or delayed shifts.

Contaminated or degraded transmission fluid is another common cause. As fluid ages, it can accumulate debris and lose its effectiveness, leading to poor lubrication and hydraulic performance—both of which contribute to harsh or erratic shifting.

-

Question 39 of 60

39. Question

1 pointsTechnician A and B is diagnosing the DTC P0705 PNP (park/neutral position) switch circuit. Technician A says that the code is set when the TCM or PCM doesn’t receive the appropriate voltage signal from the PNP switch. Technician B says that the PNP switch circuit could be shorted or open. Who is CORRECT?

Correct

Both Technician A and Technician B are correct.

Diagnostic Trouble Code (DTC) P0705 is triggered when the Transmission Control Module (TCM) or Powertrain Control Module (PCM) does not receive the correct voltage signal from the Park/Neutral Position (PNP) switch. Technician A is correct in stating that the code is set due to the absence of the proper signal from the PNP switch, which can result from issues such as a faulty switch, wiring problems, or a malfunctioning control module.

Technician B is also correct in noting that a short or open circuit in the PNP switch circuit can cause this loss of signal. Therefore, both the signal issue and potential circuit faults are valid causes of the P0705 code.

Incorrect

Both Technician A and Technician B are correct.

Diagnostic Trouble Code (DTC) P0705 is triggered when the Transmission Control Module (TCM) or Powertrain Control Module (PCM) does not receive the correct voltage signal from the Park/Neutral Position (PNP) switch. Technician A is correct in stating that the code is set due to the absence of the proper signal from the PNP switch, which can result from issues such as a faulty switch, wiring problems, or a malfunctioning control module.

Technician B is also correct in noting that a short or open circuit in the PNP switch circuit can cause this loss of signal. Therefore, both the signal issue and potential circuit faults are valid causes of the P0705 code.

-

Question 40 of 60

40. Question

1 pointsTo fulfill the needs of an automatic transmission, which transmission pump changes its flow rate?

Correct

A variable-displacement vane pump is commonly used in automatic transmissions because it can adjust its flow rate to meet the system’s changing demands. Automatic transmissions rely on a consistent supply of pressurized fluid for proper operation, especially during gear shifts and varying load conditions.

This type of pump works by altering the angle of its vanes, which changes the volume of fluid displaced with each rotation. By adjusting the vane angle, the pump can increase or decrease fluid flow as needed, providing precise control over hydraulic pressure. Its efficiency and adaptability make the variable-displacement vane pump a preferred choice in modern automatic transmissions.

Incorrect

A variable-displacement vane pump is commonly used in automatic transmissions because it can adjust its flow rate to meet the system’s changing demands. Automatic transmissions rely on a consistent supply of pressurized fluid for proper operation, especially during gear shifts and varying load conditions.

This type of pump works by altering the angle of its vanes, which changes the volume of fluid displaced with each rotation. By adjusting the vane angle, the pump can increase or decrease fluid flow as needed, providing precise control over hydraulic pressure. Its efficiency and adaptability make the variable-displacement vane pump a preferred choice in modern automatic transmissions.

-

Question 41 of 60

41. Question

1 pointsLook at the picture below, what should NOT you check on inspecting the flex plate?

Correct

Correct

Automatic transmissions generally do not use a crankshaft pilot bearing. This component is typically found in manual transmission systems, where it supports the input shaft and ensures smooth rotation. Installed in the center of the flywheel or flexplate, the pilot bearing allows the manual transmission’s input shaft to align and rotate properly with the engine’s crankshaft.

Incorrect

Automatic transmissions generally do not use a crankshaft pilot bearing. This component is typically found in manual transmission systems, where it supports the input shaft and ensures smooth rotation. Installed in the center of the flywheel or flexplate, the pilot bearing allows the manual transmission’s input shaft to align and rotate properly with the engine’s crankshaft.

-

Question 42 of 60

42. Question

1 pointsThe automated transmission shifts smoothly in all gears except for second gear, where it experiences difficulty shifting. Technician A believes this is due to a malfunctioning accumulator. Technician B believes the accumulator has a broken spring. Who is CORRECT?

Correct

Both Technician A and Technician B could be correct, as a faulty accumulator or a broken accumulator spring can lead to difficulty shifting into second gear in an automatic transmission.

The accumulator is a hydraulic component designed to smooth out and regulate line pressure during gear changes. If it malfunctions, it may fail to supply the proper pressure needed for a smooth transition into second gear, causing shift hesitation or harshness.

Likewise, a broken spring inside the accumulator can disrupt pressure regulation, making it difficult for the transmission to engage second gear properly. Both issues can result in similar shifting problems.

Incorrect

Both Technician A and Technician B could be correct, as a faulty accumulator or a broken accumulator spring can lead to difficulty shifting into second gear in an automatic transmission.

The accumulator is a hydraulic component designed to smooth out and regulate line pressure during gear changes. If it malfunctions, it may fail to supply the proper pressure needed for a smooth transition into second gear, causing shift hesitation or harshness.

Likewise, a broken spring inside the accumulator can disrupt pressure regulation, making it difficult for the transmission to engage second gear properly. Both issues can result in similar shifting problems.

-

Question 43 of 60

43. Question

1 pointsWhat is the reason for the shift of the fluid color on an automatic transmission from light to dark brown?

Correct

Brown or dark brown transmission fluid indicates that the fluid has lost its viscosity and is undergoing oxidation. Oxidation occurs when the fluid becomes aerated, reducing its ability to lubricate and protect the transmission. If your transmission fluid has turned this color, it should be changed immediately.

Overfilling or underfilling can accelerate oxidation, darkening the fluid. Water contamination may cause the fluid to appear lighter or take on a pinkish hue, while friction material wear can turn it dark brown or even black. Additionally, contamination from engine coolant can result in a milky or frothy appearance.

However, fluid color alone is not always a reliable diagnostic tool. Different types of contamination can produce similar visual changes. Other signs—such as burnt odors, erratic shifting, or slipping—should also be considered when assessing potential transmission issues.

Incorrect

Brown or dark brown transmission fluid indicates that the fluid has lost its viscosity and is undergoing oxidation. Oxidation occurs when the fluid becomes aerated, reducing its ability to lubricate and protect the transmission. If your transmission fluid has turned this color, it should be changed immediately.

Overfilling or underfilling can accelerate oxidation, darkening the fluid. Water contamination may cause the fluid to appear lighter or take on a pinkish hue, while friction material wear can turn it dark brown or even black. Additionally, contamination from engine coolant can result in a milky or frothy appearance.

However, fluid color alone is not always a reliable diagnostic tool. Different types of contamination can produce similar visual changes. Other signs—such as burnt odors, erratic shifting, or slipping—should also be considered when assessing potential transmission issues.

-

Question 44 of 60

44. Question

1 pointsA transmission brake band_______.Correct

A transmission brake band is a braking component used in automatic transmissions. It wraps around a drum or rotating element and is applied using hydraulic pressure to stop or hold that component in place. Its primary function is to act as a stopping or holding device—it does not engage or drive the members of the planetary gear set.

Incorrect

A transmission brake band is a braking component used in automatic transmissions. It wraps around a drum or rotating element and is applied using hydraulic pressure to stop or hold that component in place. Its primary function is to act as a stopping or holding device—it does not engage or drive the members of the planetary gear set.

-

Question 45 of 60

45. Question

1 pointsDuring a transmission fluid check, the technician sees that the ATF appears milky. Which of the following COULD be the reason?

Correct

If the transmission fluid appears milky, it likely indicates contamination from water or coolant mixing with the ATF. This is most often caused by a leak in the transmission cooler, which is typically located inside the radiator. When the cooler fails, coolant can enter the transmission fluid, resulting in the milky appearance.

Among the possible causes, an oil cooler leak is the most probable—not a slipping band, overheating, or oxidation. It’s crucial to address this issue promptly, as operating the transmission with contaminated fluid can cause significant internal damage.

Incorrect

If the transmission fluid appears milky, it likely indicates contamination from water or coolant mixing with the ATF. This is most often caused by a leak in the transmission cooler, which is typically located inside the radiator. When the cooler fails, coolant can enter the transmission fluid, resulting in the milky appearance.

Among the possible causes, an oil cooler leak is the most probable—not a slipping band, overheating, or oxidation. It’s crucial to address this issue promptly, as operating the transmission with contaminated fluid can cause significant internal damage.

-

Question 46 of 60

46. Question

1 pointsAccording to Technician A, an automatic transmission multiple friction disc clutch can drive a planetary gearset component. A multiple friction disc clutch, according to Technician B, can ground a member to the transmission case. Who is CORRECT?

Correct

Both technicians are correct.

Technician A is right in stating that a multiple friction disc clutch in an automatic transmission can drive a component of the planetary gearset. These clutches engage and disengage specific gearset members, allowing for changes in gear ratios during operation.

Technician B is also correct. A multiple friction disc clutch can serve to ground a planetary gearset member to the transmission case. When applied, the clutch locks the rotating component to the stationary case, effectively holding it in place. This mechanical grounding is essential for proper gear function and is unrelated to electrical grounding.

Incorrect

Both technicians are correct.

Technician A is right in stating that a multiple friction disc clutch in an automatic transmission can drive a component of the planetary gearset. These clutches engage and disengage specific gearset members, allowing for changes in gear ratios during operation.

Technician B is also correct. A multiple friction disc clutch can serve to ground a planetary gearset member to the transmission case. When applied, the clutch locks the rotating component to the stationary case, effectively holding it in place. This mechanical grounding is essential for proper gear function and is unrelated to electrical grounding.

-

Question 47 of 60

47. Question

1 pointsWhich of the following options is NOT the issue leading to the excess speed when shifting in an automatic transaxle?

Correct

Weak governor spring tension is unlikely to cause excessive speed during shifting in an automatic transaxle. Instead, it typically leads to delayed upshifts and slower shift timing.

However, a sticking governor valve can prevent the transmission from shifting at the correct speed, causing the vehicle to reach higher speeds before upshifting. Similarly, excessive governor spring tension can lead to overly aggressive or early governor response, resulting in abrupt shifting and increased speed during gear changes.

Additionally, worn governor weights or pins can interfere with the governor’s ability to accurately sense vehicle speed. If these components are worn or sluggish, they can delay or disrupt shift timing, potentially contributing to excessive speed during shifts.

Incorrect

Weak governor spring tension is unlikely to cause excessive speed during shifting in an automatic transaxle. Instead, it typically leads to delayed upshifts and slower shift timing.

However, a sticking governor valve can prevent the transmission from shifting at the correct speed, causing the vehicle to reach higher speeds before upshifting. Similarly, excessive governor spring tension can lead to overly aggressive or early governor response, resulting in abrupt shifting and increased speed during gear changes.

Additionally, worn governor weights or pins can interfere with the governor’s ability to accurately sense vehicle speed. If these components are worn or sluggish, they can delay or disrupt shift timing, potentially contributing to excessive speed during shifts.

-

Question 48 of 60

48. Question

1 pointsAccording to Technician A, a defective transmission range sensor will prevent the starter from working. Technician B recommends using an ohmmeter to test an analog transmission range sensor. Who is CORRECT?

Correct

The transmission range sensor, also known as the neutral safety switch or gear position sensor, is responsible for detecting the position of the gear selector and allowing the vehicle to start only in “Park” or “Neutral” positions. If the sensor is faulty, it may prevent the vehicle from starting in the correct gear, but it does not directly affect the starter’s operation.

Technician B is also correct. An ohmmeter is a device used to measure electrical resistance, and it can be used to test the continuity and resistance of various components, including the transmission range sensor. By measuring the resistance across different terminals of the sensor, one can determine if it is functioning within the specified range or if it is faulty.Incorrect

The transmission range sensor, also known as the neutral safety switch or gear position sensor, is responsible for detecting the position of the gear selector and allowing the vehicle to start only in “Park” or “Neutral” positions. If the sensor is faulty, it may prevent the vehicle from starting in the correct gear, but it does not directly affect the starter’s operation.

Technician B is also correct. An ohmmeter is a device used to measure electrical resistance, and it can be used to test the continuity and resistance of various components, including the transmission range sensor. By measuring the resistance across different terminals of the sensor, one can determine if it is functioning within the specified range or if it is faulty. -

Question 49 of 60

49. Question

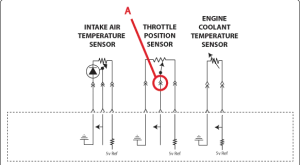

1 pointsComponent A in the schematic diagram is

__________. Correct

Correct

This is the connector used in the signal circuit of the Throttle Position (TP) sensor.

In wiring diagrams, a splice is indicated by a solid black dot and represents the connection point where two or more wires are joined. In the TP sensor’s signal circuit, this connector is part of that splice. The schematic symbol showing this connection uses the black dot to illustrate the joined wires.

Additionally, the reference voltage circuit is labeled as 5V ref, indicating a 5-volt supply used as a reference for sensor operation.

Incorrect

This is the connector used in the signal circuit of the Throttle Position (TP) sensor.

In wiring diagrams, a splice is indicated by a solid black dot and represents the connection point where two or more wires are joined. In the TP sensor’s signal circuit, this connector is part of that splice. The schematic symbol showing this connection uses the black dot to illustrate the joined wires.

Additionally, the reference voltage circuit is labeled as 5V ref, indicating a 5-volt supply used as a reference for sensor operation.

-

Question 50 of 60

50. Question

1 pointsA computer-controlled transaxle will not shift into fourth gear. According to technician A the battery voltage should be tested. While technician B thinks that diagnostics should be started with a basic inspection of hoses and wires. Who is CORRECT?